Steel tubing is an absolute staple when it comes to innovation in facilities and buildings. From developing robust structural frameworks and mighty frameworks to constructing machinery and tools, the content and potential applications are staggering. The weight of steel tubing is an important quantifier when considering its durability, powering it to become a go-to material for producing strong, reliable works of engineering.

A steel tube’s heft may be estimated by taking into account its form and dimensions. Generally, as the size of a tube swells and its walls become more plentiful, so does its mass. Moreover, the more protracted a tube, the heavier it tends to be in comparison to shorter alternatives.

With regards to the weight of a steel pipe, considering the alloy it is composed of can be pivotal. In point of fact, the density of the steel itself is a determinant in determining its mass; for example, more lightweight mild steel will lead to a lighter tube than a heavier stainless steel of the same size.

When in the need of steel tube sections, make sure you are aware of the exact weight that you are looking to order. To discover this information, you have the option of consulting the technical data sheet specific to your tube or connecting with the manufacturer. Within the technical data sheet, details such as length, wall thickness, and the type of steel utilized in this tube will normally be provided.

Steel tubes come in a variety of sizes, stemming from measurements taken in millimeters or inches. To ascertain their weight, the tube’s mass should be calculated in either kilograms or pounds. The equation for this calculation involves multiplying together the wall thickness, length, and the density of the steel.

Making sure you select steel tube sections of the right weight is critical when ordering pieces for any application. If the weight of the tube is too great, it can weaken the stability of the structure or product. On the other hand, if the tube is too lightweight, it might not withstand the load that is placed upon it.

The weight of the steel tube section alone does not tell us the whole story. There are other equally important elements to consider, such as the wall thickness, tube length, and the grade of steel used. All come together to determine how strong and sturdy the structure or device may be. Taking into account all of these details is key in order to pick a tube that is up to the task.

Steel tube sections are an invaluable resource, providing incredible utility and flexibility for various industries. However, when ordering, it is wise to be mindful of the weight of the tube in question. Taking into account the many factors that contribute to a tube’s weight helps ensure that the right tube is ordered for any given application.

When choosing the right materials for a project, the weight of steel tube sections must be taken into account. These tubes can be utilized in construction developments, vehicles and planes, or a few other production processes. Not only is their heaviness crucial for stability, but it’s also a major factor that affects the cost. Therefore, knowledge of steel tube section weight is key to making the most suitable decision for any task.

A variety of components are taken into consideration when gauging the heft of steel tubing. The size, measured through diameter and wall thickness, is of significant consequence: larger, thicker-walled tubes inherently have a higher mass. Just as influential is the material utilized in production, with distinct alloys – such as stainless steel or carbon steel – creating discrepancies in weigh. Consequently, the size and composition of the tube will greatly impact its overall weight.

The heft of steel tube sections is affected by much more than just the raw material – fabrication technique, surface coating, and end treatment also play a role. For example, hot-rolled tubes are typically heavier than those that are cold-rolled. Moreover, several types of coatings can be applied to the tube to give it additional weight. To conclude, the way in which tubes are finished off – through welding or machining – can also have an effect on their mass.

Before pinpointing the weight of any steel tubing, several considerations need to be made. It is imperative to assess its diameter, its wall thickness, the kind of steel used, plus any surface treatments or finishing touches. These measurements will then be feeded into a regular formula to provide an exact figure for the weight of the tube.

The burden of steel tube sections holds sizable sway in budgeting, as it can impact the amount of material a project will require and even the cost of transiting. Put simply, the heavier the tube, the more materials and fuel will be necessary, thus driving up the total cost for the project.

The selection of suitable steel tube for a given project requires more than only a single factor to be measured: the weight. Strength, corrosion resistance, and other characteristics must all be deliberated when opting for the correct tube. By weighing up all these qualities, the ideal choice of steel tube can be confidently established.

Post time: 2023-07-09

Related Product

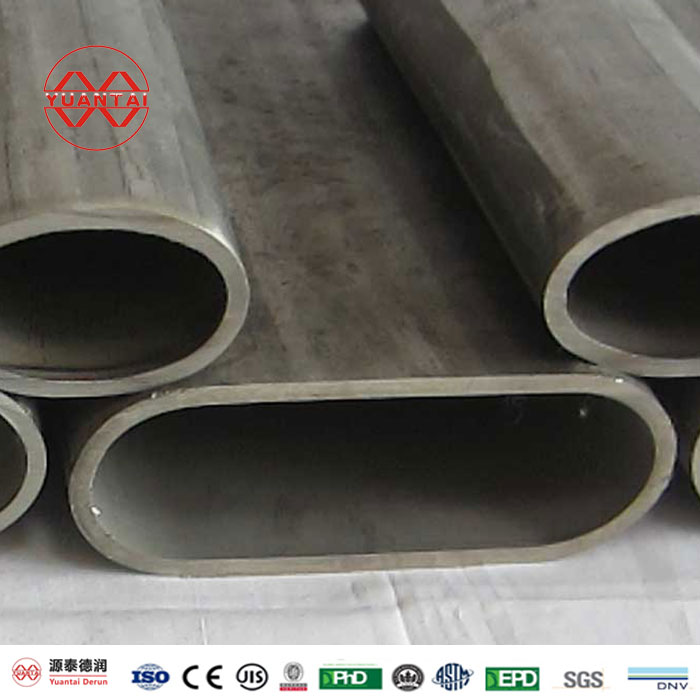

Wholesale Hot-Dip Galvanized Oval Pipe Q235B Galvanized Steel Pipe Installation Of Bendable Greenhouse Pipe

The energy-saving solar greenhouse is the most economical and practical greenhouse type among greenhouse types, because this type of greenhouse can be used for winter vegetable cul […]

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]

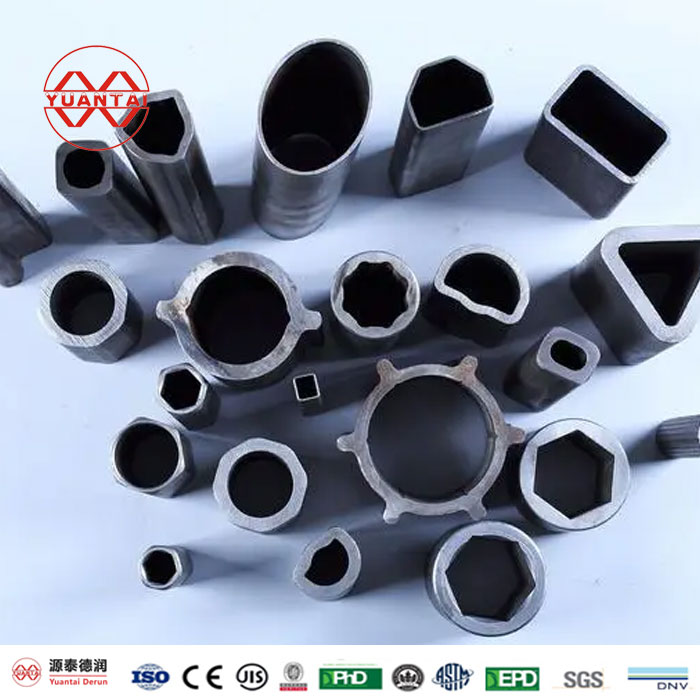

Octagonal Steel Pipe

Tianjin Yuantai Derun Group has 18 wholly-owned subsidiaries, of which Tianjin Yuantai Technology Development Co., Ltd. was founded in 2014 to produce super large diameter, super t […]

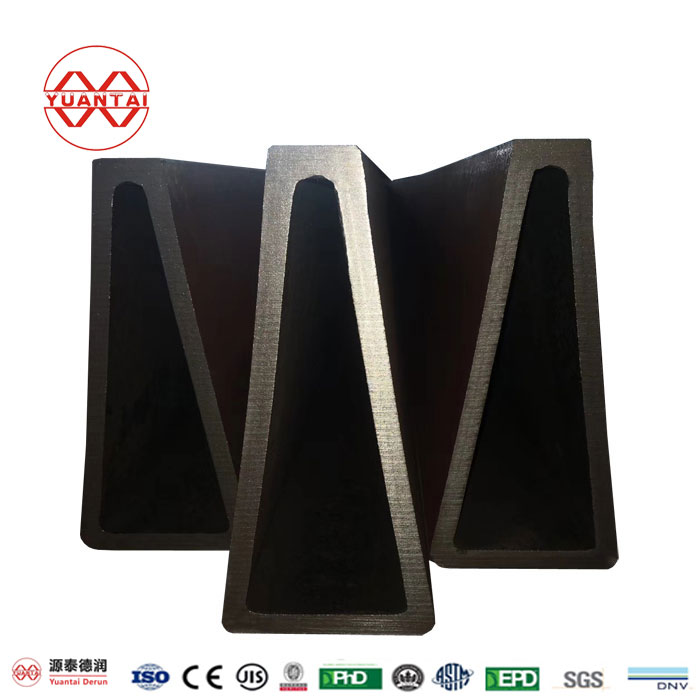

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]

Supply Of Zigzag Steel Clips New Type Of Zigzag Steel Framework Connecting Clips

Product name: Jizi steel skeleton accessories Product alias: zigzag steel card, zigzag steel bending connection Product description: The framework of the shed is made of zigzag ste […]

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]