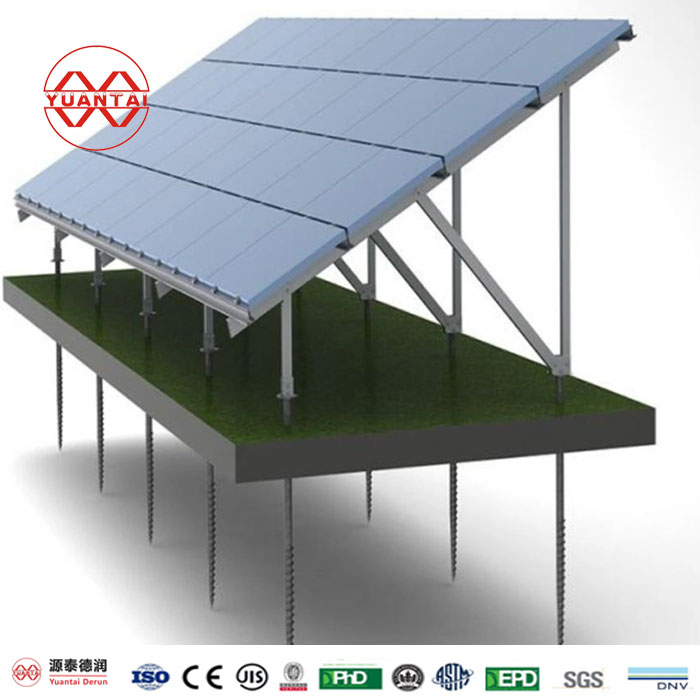

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended to be popularized. Steel spiral piles include hollow cylindrical piles and solid circular or polygonal piles.

Steel spiral piles are divided into cylindrical hollow piles and circular or polygonal solid piles. Steel screw pile is a widely used screw pile with excellent strength performance, economy and durability. The length of the spiral pile is used for the reinforcement and fixation of the bridge.

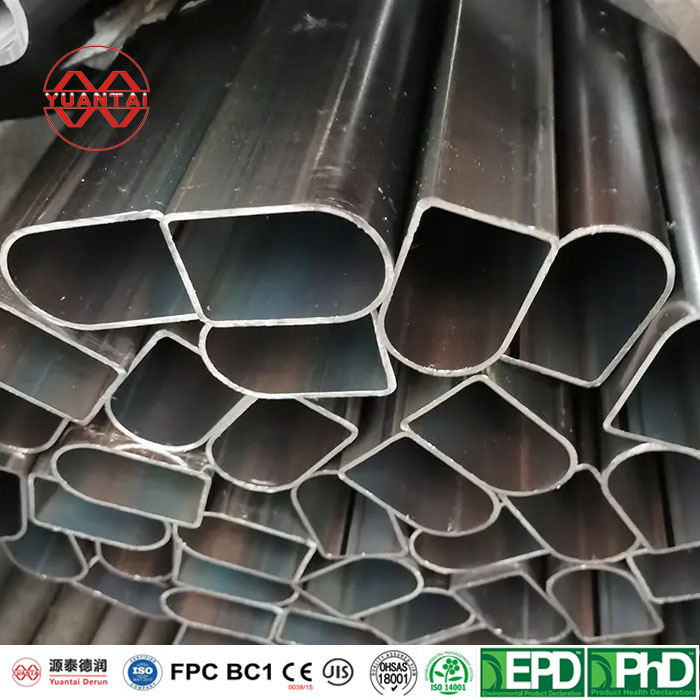

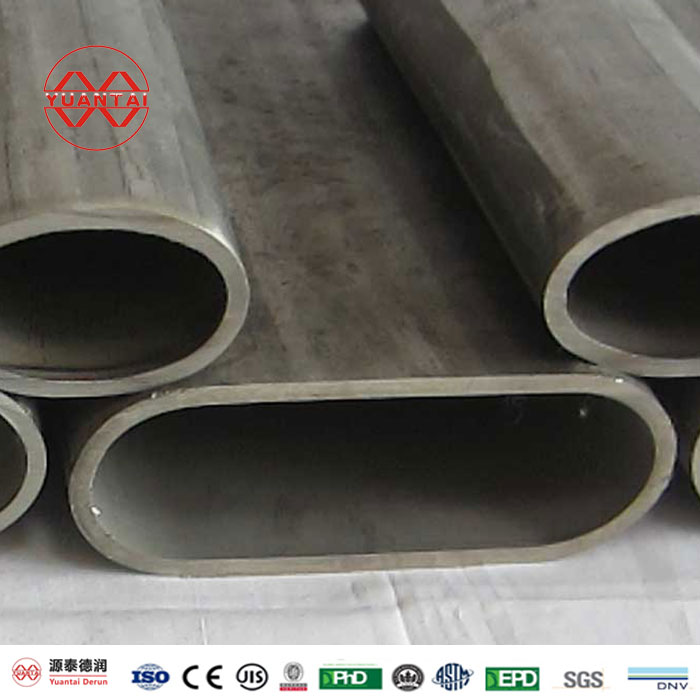

Hollow pile and solid pile

The hollow pipe joint of reinforced concrete is twisted by a special steel hook inside the pile shaft. The torsional moment of the winch is transferred to the pile at the level of the rotary vane.

In order to increase the strength of the pile shaft, hollow pipe joints must be made of prestressed reinforced concrete. Due to the complexity and difficulty of manufacturing and twisting, the hollow reinforced concrete screw pile has not been used up to now.

The reinforced concrete spiral pile with solid section is relatively simple in structure. This pile is made of high-strength ordinary concrete, and the concrete grade is 300~400 kg/cm2. It is twisted with a regular steel casing sleeved on the spiral pile.

This type of reinforced concrete screw pile was used once when a bridge was built from 1951 to 1952. The pile shaft is about 500 mm in diameter and is made of 300 grade concrete. The pile shoes are made of cast iron. The diameter of the rotor blade is 1.5 meters. The sinking depth of the pile is about 8 meters. The average speed of sinking in the soil is between 7 and 8 meters/hour. The total time for sinking a screw pile with a length of 8.5~9 meters, including all preparations, is less than 4 hours.

On another bridge, this kind of reinforced concrete spiral pile is also used, and its sinking depth is more than 17 meters. The pile shaft is an octagonal solid section with an outer diameter of 4.50 mm. The concrete is Class 300. The pile shoe is made of steel, and its rotary vane has a triangular section. The diameter of rotary blade is 1.4 meters. All spiral piles are sinking into the soil at a slope of 5:1 to 5.5:1 at different speeds. The maximum speed change of the pile is 13~13.5 m/h. Minimum speed; Only one pile has this speed, which is about 3 meters/hour. The average sinking speed is 7.6 m/h. The screw piles used in these two bridges were screwed in by the winch of the Central Academy of Sciences in 1945.

The construction organization of these two bridges is roughly the same. The torsional moment of each pile is 30~35 tons/meter, which is transmitted to the pile shoe by the winch through the standing casing laying. When the pile shoe and pile shaft sink, the standing steel casing shall be pulled out from the soil for the next pile screwing.

The factory has passed the ISO9000 01 and the environmental quality certification ISO14001. The screw ground screw has passed the certification of TUV, BV and CE of Germany, France, and has a number of invention patents, appearance patents and utility model patents. The products are made of steel. The hot-dip galvanizing requirements are higher than the national standard, and the product life is guaranteed to be more than 50 years.

Reference parameter: material: Q195/Q235/Q345

Surface treatment: hot galvanizing ≥ 80 μ m

- Length: 1200-3500mm

- Outer diameter: 60-219mm

- Wall thickness: 2.75-6mm

- Pitch: 50-200 ㎜

- Flange plate: 200 × 8mm

- Blade: Ф 176mm/189mm/214mm × 4mm-5mm

Production Detail: