In many modern engineering projects, the capacity of steel tubes to bear weights is a crucial component. These tubes are employed in a multitude of projects, including structural frameworks, pipe foundations, and columns for bridges. Boasting remarkable tensile strength, malleability, and a superior resistance to wear and tear, steel tubes are the perfect choice for loading applications.

The resilience of a steel tube is dictated by various factors including the grade of steel it is made from, its dimensions, as well as its wall thickness. Each steel grade has its own individual properties which influence the tubing’s toughness – the larger the tube and thicker the wall, the more formidable it will be.

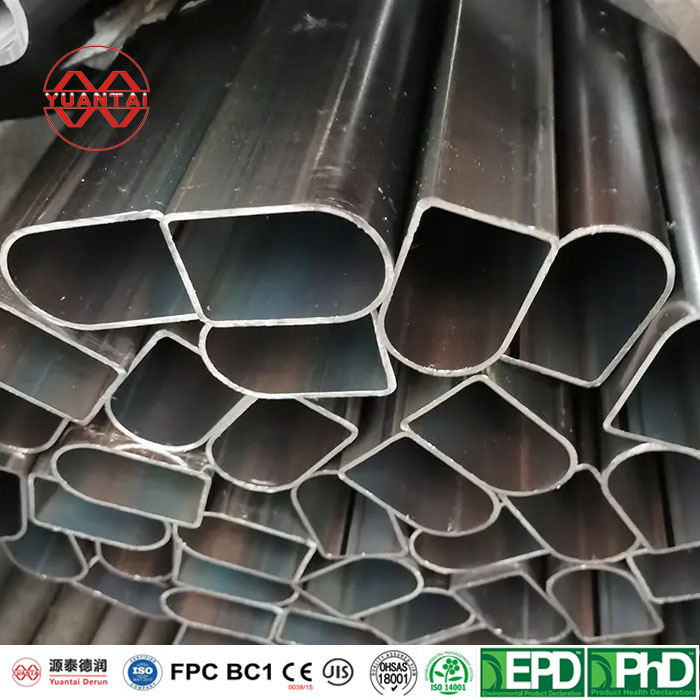

When considering the carrying power of a steel tube, its figure is paramount – round tubes being the prevailing and toughest when it comes to structural use. However, square tubes can be utilized for purposes such as pipe stands and bridge posts. The load-bearing capacity of a steel tube is also influenced by the type of load it holds – static loads usually remain constant while dynamic loading can shift over time.

Before constructing a structure, engineers must evaluate the load-bearing potential of steel tubes. This entails computing the maximum amount of load the and element can take without damage. Material components, dimensions, shape, wall thickness, and the imposed load all factor into the assessment. It is important to accurately consider both static and dynamic loading when considering a tube’s capacity to bear stress.

Steel tubes often employ welded or bolted connections to join the tube with other components, and the type of connection has an influence on its load bearing capacity. Take, for example, that welded joints typically provide greater strength than bolted joints. Therefore when engineers compute the load bearing capacity of a steel tube they must also take into consideration the chosen method of connection.

In considering a steel tube for its load bearing capacity, fatigue resistance must not be overlooked. Constantly repetitive loading can often weaken the strength of the material over time, a phenomenon known as fatigue. Opting for a steel tube with an impressive ability to resist fatigue is thus very important.

As engineers face the challenge of developing steel tubes, their last task is to analyze the atmosphere that the tube will exist in. The corrosive nature of some environments can lead to a decrease in the reliability of any steel tube that is utilized; therefore, it is pivotal to pick a grade of steel that offers protection from erosion.

For sound building design, it is vital to account for the load-bearing capacity of steel tubes; an integral part of many structures. Material property, size, shape, wall thickness and type of expected loading all give insight into a tube’s load-bearing factor. With this knowledge, architects can contemplate structures that are safe and lasting.

Appraising Steel Tube Load-Bearing Strength

Steel tube offers a range of characteristics that are vital for engineers, architects and builders – its load capacity being among the most notable. Depending on the kind of steel used, and the environment in which it is placed, load bearing capacities may vary. To further explore this subject, this article will provide an overview of the various types of steel tube and their respective load bearing capabilities.

A hollow cylinder made of steel, steel tube is a ubiquitous component in modern engineering and construction projects. It serves an essential purpose, forming the bone and sinews of a wide variety of structures from bridges and buildings to industrial machines and equipment. Indeed, without steel tube, the world around us would look incredibly different.

The load bearing capacity of a steel tube is a crucial element when deciding on which steel tube to use for any particular project. This capacity will dictate the weight, which the steel tube can withstand before it becomes compromised. Several variables will cause this capacity to alter, such as the material used, the wall thickness, the diameter of the steel tube, and even where it is utilized and attached to other parts.

When engineers and construction companies need a dependable, cost-effective material for load-bearing construction projects, they often turn to carbon steel tubes. This alloy of various metals, including iron and carbon, is renowned for its strength and durability as well as its ability to withstand corrosion. Therefore, carbon steel is often the preferred choice for all kinds of designing and building applications.

Carbon steel tube load capacity is decided by its wall thickness, diameter, and the specific steel employed. Generally, the thicker the wall, the larger the scope of its load bearing. As well, a greater diameter of the steel tube influences its load capacity as it can bear a larger load.

The maximum load which a steel tube can withstand is significantly dependent on the environment where it is used. For example, if a steel tube is positioned outside, it must be protected from corrosion by the proper coatings and treatments. Moreover, drastic shifts in temperature and humidity can cause considerable variations in the robustness of the steel tube.

The load-bearing capacity of steel tube is ultimately dependent upon how it is affixed to other components. Welding, bolting, and riveting are the three main methods typically used to link steel tube with other parts; however, each option possesses its own merits and drawbacks which should be carefully weighed in relation to the anticipated environment and purpose of the assembly.

Ultimately, the ability of a steel tube to uphold loads will vary depending on its material make-up, dimensions, placement environment, and how it is annexed to other parts. Boasting both versatility and durability, steel tube is an exceptional option for a variety of projects; it’s pivotal to contemplate its load bearing potential ahead of implementing it in any undertaking.

Post time: 2023-08-16

Related Product

Octagonal Steel Pipe

Tianjin Yuantai Derun Group has 18 wholly-owned subsidiaries, of which Tianjin Yuantai Technology Development Co., Ltd. was founded in 2014 to produce super large diameter, super t […]

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

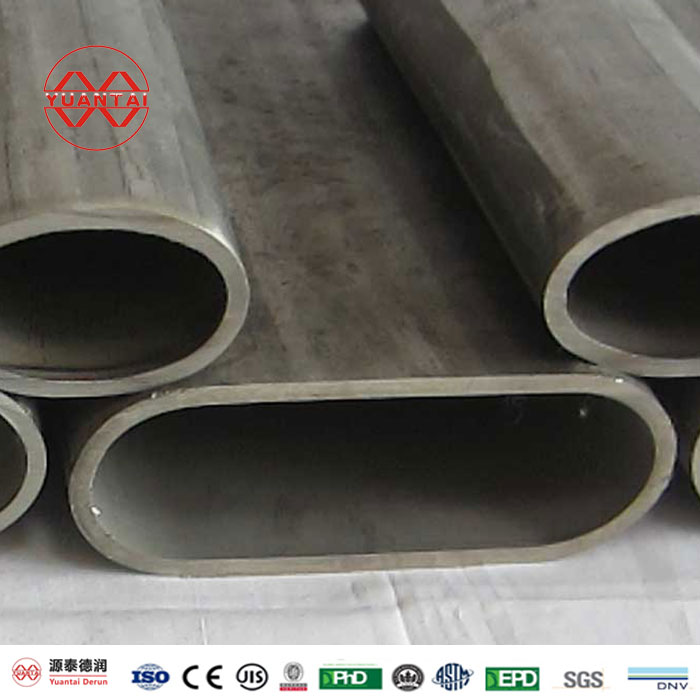

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

Greenhouse Shed Circlip Dipped Plastic Circlip Manufacturer Wholesale Cartridge Compression Spring Greenhouse Accessories Slot Circlip

Greenhouse shed circlip dipped plastic circlip manufacturer wholesale cartridge compression spring greenhouse accessories slot circlip

Supply Of Zigzag Steel Clips New Type Of Zigzag Steel Framework Connecting Clips

Product name: Jizi steel skeleton accessories Product alias: zigzag steel card, zigzag steel bending connection Product description: The framework of the shed is made of zigzag ste […]

Wholesale Hot-Dip Galvanized Oval Pipe Q235B Galvanized Steel Pipe Installation Of Bendable Greenhouse Pipe

The energy-saving solar greenhouse is the most economical and practical greenhouse type among greenhouse types, because this type of greenhouse can be used for winter vegetable cul […]

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

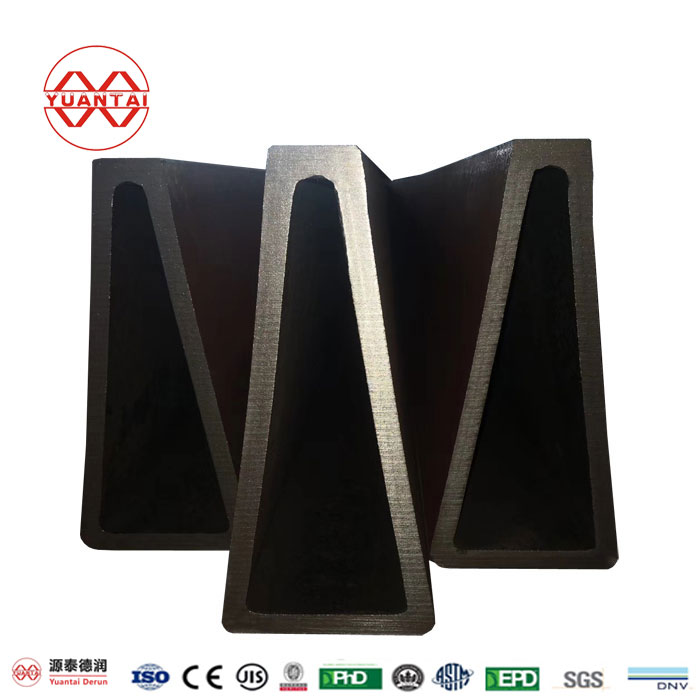

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]