Acknowledged throughout the world for their impressive sturdiness, corrosion resistance, and longevity, stainless steel tubes are a popular choice across both industries and households. They come in a range of shapes and sizes, meaning they can be utilized for multiple purposes without compromising their noteworthy traits.

Metals like iron, chromium, and nickel are combined to produce stainless steel tubes that are impressively resilient against corrosion, rust, and harm of any kind. Chromium in the alloy gives rise to a thin layer of oxide coating on the metallic surface, adamantly blocking the emergence of rust or any other type of destruction. Furthermore, the inclusion of nickel fortifies the strength of the tube – making it more resistant to wear-and-tear and enhancing its durability.

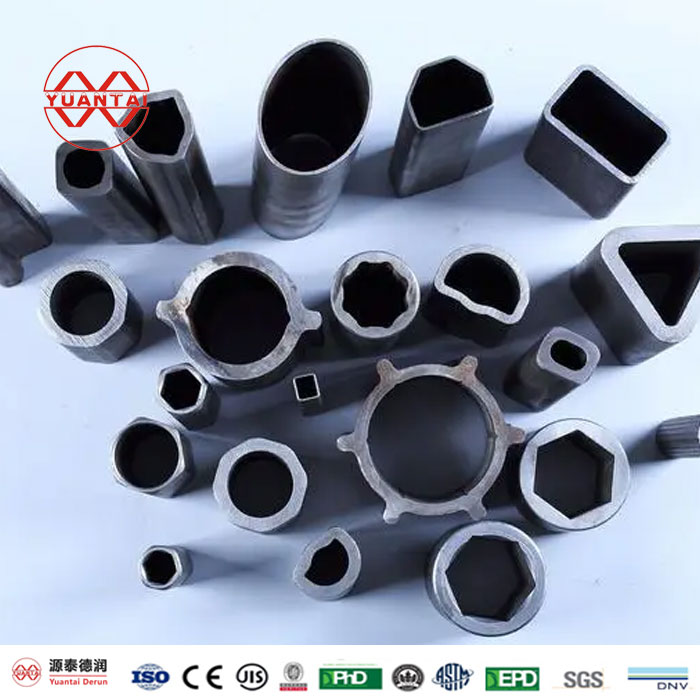

Stainless steel tubes provide an array of options for any sort of task; from round shaped cylinders to rectangular, square, or even oval. The thickness and grade of the tube also varies accordingly, ensuring that each tube is optimized for its designated purpose.

Stainless steel tubes provide invaluable service in both structural and consumer applications. They contribute tremendous sturdiness to constructions like bridges and buildings, as well as providing needed support for pipes. Additionally, their strong resistance to corrosion and capacity to tolerate high temperatures make them the preferred choice when manufacturing everyday items, such as kitchen appliances or sinks.

Stainless steel tubes are a favorite of the automotive world – from exhaust systems and fuel lines to vehicle components, these tubes offer reliable corrosion resistance and can confidently exist in even the harshest of conditions. Not only are they trusted by cars, but boats and ships also make use of their durable capabilities.

The food and medical industries both rely on stainless steel tubes for transporting materials from one location to another. This type of tube has the ability to resist bacteria and other types of contaminants, making it the perfect option for these fields of work.

Stainless steel tubes can be found in the assembly of countless plumbing setups – both in businesses and residences alike. From heaters to filters, these specialized pipes are an essential element in ensuring that the water runs clean and hot.

Exhibiting remarkable longevity and robustness, stainless-steel tubes are sought after for projects of any scale. An abundant offering of sizes and grades make them a versatile choice, while their cost-effectiveness makes them attractive to all kinds of budgets. Immunity to corrosion only increases their appeal – stainless steel tubes have it all!

Stainless steel tube steel is a remarkably tough material, possessing exceptional strength and durability. It also offers remarkable corrosion-resistance in the face of heat and pressure, making it a popular choice for the fabrication of tubes, pipes, and components used in a multitude of industries across the globe.

The construction of stainless steel tubes requires certain steps to be taken. Initially, the base material – often iron ore – is heated in order to eliminate any contaminations and achieve a purified condition. Subsequently, this is married with chromium and nickel to form stainless steel.

Heated stainless steel is injected into a die-casting machine, where it is cooled and then cut into whatever shape is desired. With the assistance of this machine, intricate forms can be formed with supreme exactness.

Having been properly formed, the stainless steel tube is now ready for the welding phase. This involves manipulating a welding rod and heating it until molten, before adhering the two attached pieces of steel together. The approach may vary with each thickness of the material, while the fundamental welding process remains constant no matter what type of stainless steel is used.

After the act of welding has been completed, stainless steel tube steel is ready for subsequent treatments. These may take the form of machining, a practice that entails cutting and forming the metal into desired specifications. This can be accomplished either manually or with an automated method.

After extensive crafting of the stainless steel tube, the completion process involves adding an enhanced level of protection. This shields the steel from corrosion, consisting of a protective coating or sealant to create a smooth, glossy finish. Polishing and painting are incorporated to give the steel a more defined look.

Stainless steel tube steel is an exceptional material, boasting a multitude of desirable properties. Its unparalleled strength in the face of corrosion, temperatures, and pressure have made it a reliable favorite among industrialists. The process of cultivating this durable material requires complex steps such as smelting, die-casting, welding, and machining. Furthermore, an extra layer of protection is applied to ensure sustainability. These qualities render stainless steel tube steel an optimal selection for many purposes.

Post time: 2023-08-07

Related Product

Special Shaped Steel Pipe Factory

Special shaped steel pipe factory

OVAL TUBE BASE GREENHOUSE ACCESSORIES OVAL TUBE GREENHOUSE CONNECTOR CLAMP

The base of oval tube in greenhouse is no stranger to those who have been exposed to greenhouse equipment. In the installation project of greenhouse equipment, the products of oval […]

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

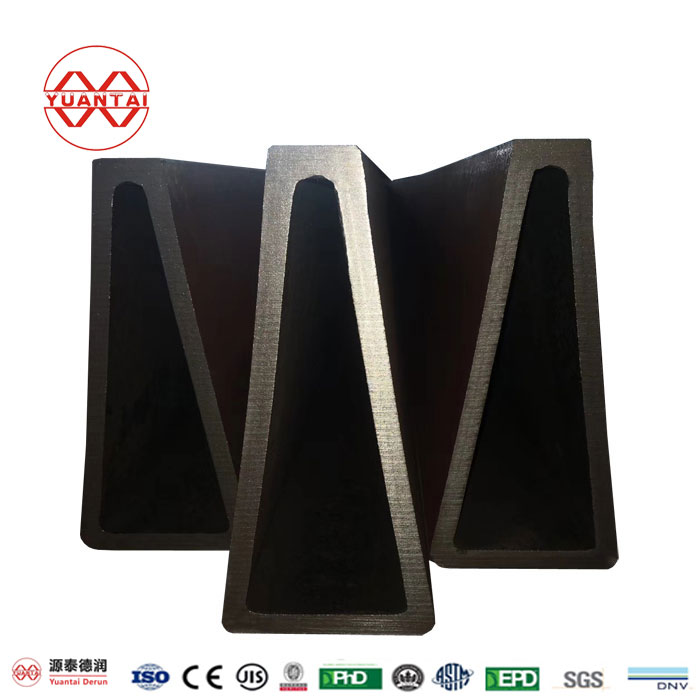

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

Greenhouse accessories Film roller, super strong side film roller Top windproof film roller

The shell is made of cast aluminum, which is cast by precision die-casting one-time molding process. Its raw materials and casting quality are in sync with the domestic top tier br […]