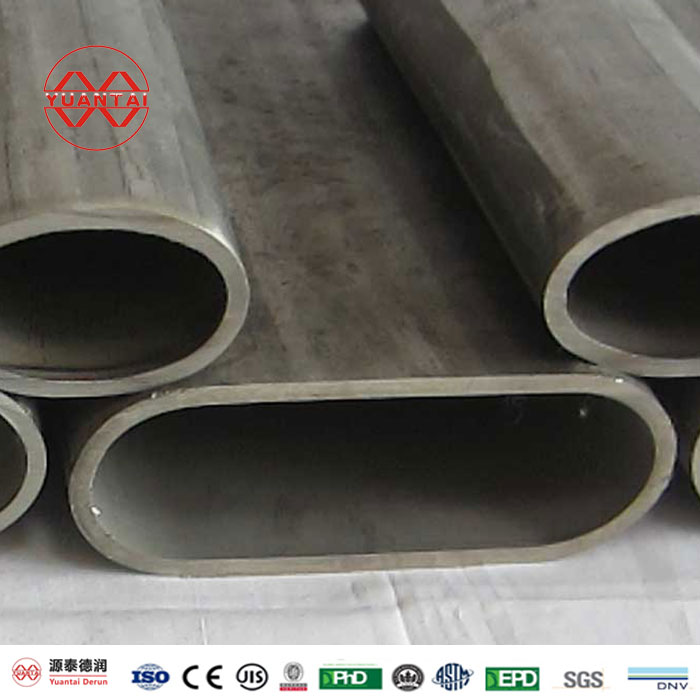

Any deviation from a perfectly cylindrical shape is referred to as an ‘ovality’ in pipes. This can be caused by a range of factors -from pressure to corrosion or vibration. While quite common, ovality can cause a decrease in performance in any piping system due to its impact on flow efficiency and accelerated wear and tear of the material. Now let’s explore this topic further and look at the what, why, and how of ovality prevention and resolution.

Exploring the Concept of Ovality

An oval shape can occur in a pipe when it is not perfectly circular, usually due to pressure or vibration. Because of the uneven pressure, the walls of the pipe are thicker and thinner in some areas. This difference causes an increased amount of friction between the pipe walls resulting in reduced flow efficiency and faster material wear and tear.

Uncovering the Sources of Ovality

The various forces of pushing and pulling can have an adverse effect on pipes. The application of pressure to a pipe can lead to its walls bending, creating an oval shaped construction. Vibration, caused as a result of continuous movement, can also cause the walls to compromise in strength and deform. Poor installation of the pipeline or piping may result in ovality if the pipe is not fitted snuggly against the adjacent walls or floors. Lastly, corrosion of metal pipes over time can cause an alteration in shape, leading to an oval conclusion.

Harnessing Tools for Avoiding Ovality

Taking precautionary measures to minimize the risk of pipe ovality is paramount for ensuring efficient and effective operations. During set-up, proper mounting of the pipes to the wall or floor will reduce their vulnerability to bending due to pressure or vibrations. Furthermore, regular evaluations of the pipes for any evidence of corrosion or wear is essential, as if they are not addressed right away, it may lead to ovality. Lastly, an ideal resources withstanding corrosion and deterioration should be selected for construction.

Confronting Ovality – Proven Tactics for Eliminating Problems.

If ovality in a piping system is present, a number of remedies exist. A particularly economical and time-saving approach is to completely swap out the problematic component with a new one that is round. A pipe expander also serves the purpose of restoring the previous cylindrical form. Lastly, pipe liners are available to patch up uneven or distorted sections, ultimately dwindling friction and tear.

The effects of ovality in pipes can be catastrophic – impacting efficiency, functionality, and durability. The causes can vary, ranging from pressure and vibration to installation errors and corrosion. To prevent this damage, it’s important to properly secure the pipes during installation and inspect them regularly for signs of wear or corrosion. Additionally, using durable materials helps increase the pipes’ longevity. If ovality has already occurred, the pipe may require replacement, expansion or a lining to make it cylindrical once again.

The once-circular cross-section of pipes can sometimes be distorted, resulting in a less-than-ideal ovular shape. This phenomenon, known as ovality in pipes, is a widespread problem that can have serious consequences on the performance and safety of piping systems. Common culprits of this issue include corrosion, inappropriate installation techniques, and badly executed welding. Unfortunately, the negative effects brought on by this unwanted change in shape can be both extensive and dangerous.

Pipe ovality is a common issue observed in metals pipes such as carbon steel, stainless steel, and aluminum. Typically, this deformity is impacted by harmful corrosion or aging. The corrosion deteriorates the metal, making it weak and resulting in an oval shape. Aging triggers wear and tear leading to thinning of material that eventually deforms and morphs into an oval shape. Additionally, inadequate welding or installation can also contribute to an oval-shaped pipe. During the welding process the extreme heat can melt the metal forming an oval shape whereas, if the installation is not done properly, the pipes being fitted together can cause bending that ultimately leads to ovality.

Over time, regular pipes can become distorted into an oval shape, often leading to significant consequences. As the fluid passes through this narrow and curved conformation, it encounters increased friction between the pipe wall, causing decreased flow. Moreover, this particular arrangement is structurally weaker compared to its usual, round state – resulting in a higher likelihood of failure or leakage. These malfunctions can prove to be extremely expensive to fix as well as a potential safety risk.

The uncanny shape of oval-shaped pipes can prove not only to be disruptive and costly, but also damaging. If the flow of the liquid in the piping system is not aligned to the pipe, it will cause constant vibrations and a loud ruckus. This can be incredibly bothersome and may even lead to harm of the system. Of course, this warped shape of the pipe won’t just disrupt, it’ll also increase costs due to its lack of maneuverability during installation and maintenance processes.

To avoid ovality, reliable materials must be chosen for pipework, welding must be exact, and regular maintenance is key. Utilization of metal that can defy corrosion and wear-and-tear is necessary for optimal design – such elements should also be firmly secured in place. Close attention must also be paid to proper installation and fastening of pipes to stave off the risk of becoming oval-shaped. Regular examinations of the closed system should also take place to guarantee its longevity and dependability of purpose.

The shape of a pipe is of the utmost importance when it comes to its functionality and safety: ovality can lead to disastrous consequences. Therefore, it is essential to take caution when using the appropriate materials and welding and fitting the pipes properly. Furthermore, frequent inspection and maintenance are necessary for any piping system to stay in top condition. Taking all these steps helps make sure that the piping system can work correctly and remain safe from any dangerous results of ovality.

Post time: 2023-08-08

Related Product

Wholesale Hot-Dip Galvanized Oval Pipe Q235B Galvanized Steel Pipe Installation Of Bendable Greenhouse Pipe

The energy-saving solar greenhouse is the most economical and practical greenhouse type among greenhouse types, because this type of greenhouse can be used for winter vegetable cul […]

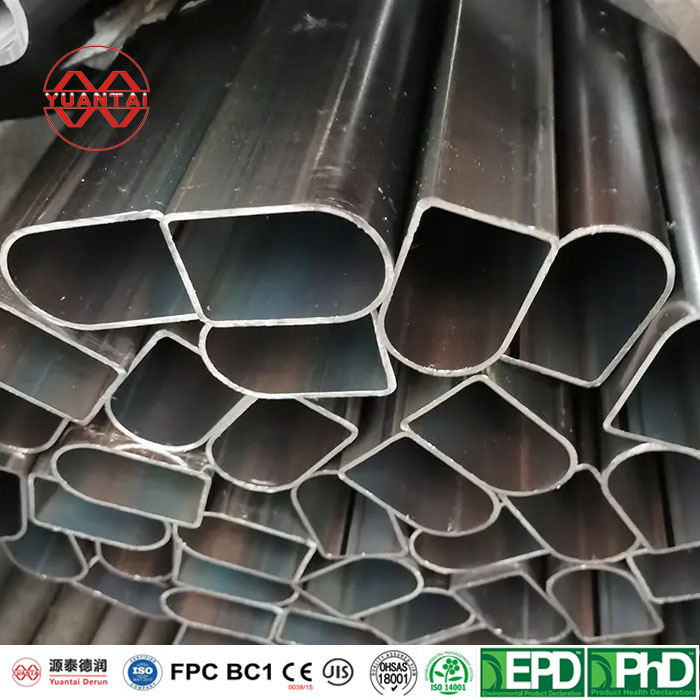

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

Supply Of Zigzag Steel Clips New Type Of Zigzag Steel Framework Connecting Clips

Product name: Jizi steel skeleton accessories Product alias: zigzag steel card, zigzag steel bending connection Product description: The framework of the shed is made of zigzag ste […]

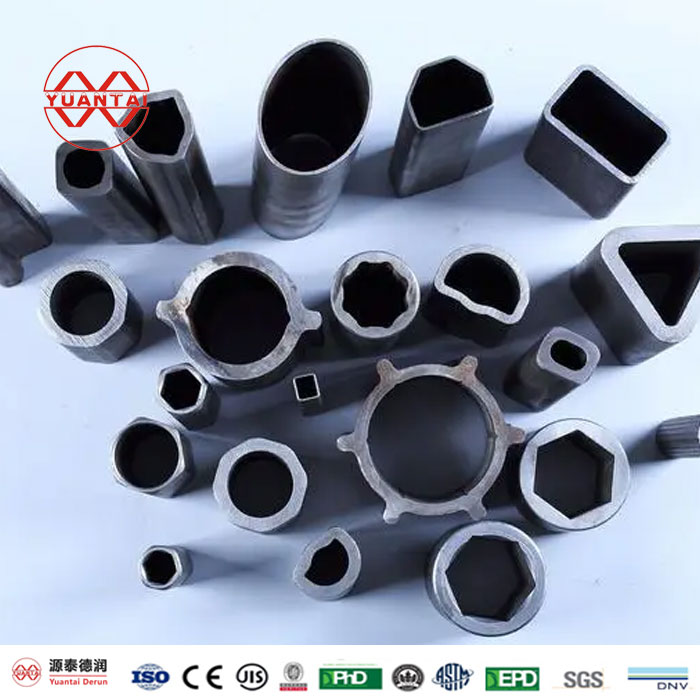

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

8-Shaped Steel Pipe

8-shaped steel pipe Product Information Brand: YuantaiDerun Place of Origin: Tianjin, China Alloy Or Not: Non-Alloy Special Pipe: Thick Wall Pipe Standard: ASTMA500/A501/A53,BS1387 […]

Special Shaped Steel Pipe Factory

Special shaped steel pipe factory

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]