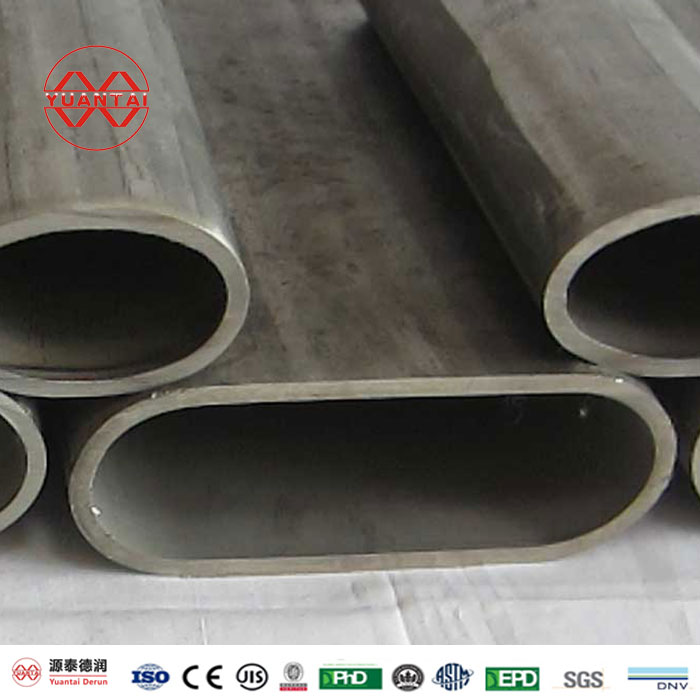

To achieve successful creation of a multitude of products, having an understanding of oval pipe sheet metal dimensions is of utmost importance. Utilizing the appropriate measurements in this area can result in the difference between a successful outcome and one that falls short. Strive to comprehend the various measurements and the related significance involved in this topic to maximize production performance.

Dual dimensions are typically used to measure oval pipe sheet metal: the outside diameter and the inside diameter. The former is the measurement of the greatest circumference of the pipe, taken from one side to the other, while the latter is the measurement of the least circumference, captured from within to out.

The weight and heft of an oval pipe sheet metal is assessed in terms of gauge. As a unit of measure, gauge helps ascertain the thickness of the metal. Greater the gauge, heavier and denser the material. For oval pipe metal sheeting, gauge is typically between 16 and 20; a range that can also be expressed in millimeters.

The length of an oval pipe sheet metal should be taken into account when being measured. This length should be calculated starting at the furthest end from the center. That measurement can either be done in inches or millimeters.

Owing to its malleability, sheet metal formed into an oval shape offers no shortage of shapes that can be crafted. Frequently used shapes are the round, rectangular, and square ones – however, looking beyond these popular shapes brings forth a world of possibility. Each shape has an effect on the dimensions of the pipe sheet metal, thereby allowing for customization depending on the desired result.

Size matters when it comes to oval pipe sheet metal: the diameter controls the width. Whether measured in inches or millimeters, the width will vary depending on how big the pipe itself is.

The heaviness of an oval pipe sheet metal is largely predicated on its thickness; the thicker the material, the weightier the pipe. It is possible to evaluate how much an individual oval pipe weighs, in either pounds or kilograms.

When dealing with oval pipe sheet metal, it is worth taking the time to determine the bend radius. This measurement determines the distance of the center of the pipe to its outer edge, and is usually specified in either inches or millimeters. In most cases, the bend radius of an oval pipe is much less than its outside diameter.

It is critical to consider the length of an oval pipe sheet metal during the fabrication process. The appropriate figure must be retrieved starting from the extremity of the circumference furthest away from its center. This data can be obtained in either inches or millimeters.

Oval pipe sheet metalpieces can come in a variety of materials, including steel, aluminum and stainless steel. Naturally, the weight, thickness and even bend radius of the item in question is affected by the type of material chosen for use.

Ultimately, those who manufacture goods must be well-versed in the dimensions of oval pipe sheet metal, as sheer familiarity with its measurements and implications is essential for a product’s success. To that end, they should know the outer diameter, internal diameter, thickness, width, weight, and curve radius required for the sheet metal. This knowledge is invaluable in producing a viable item.

Unraveling the Mystique of Oval Pipe Sheet Metal Dimensions

A fundamental knowledge of the materials applied in metal fabricating is essential for crafting high-standard items; especially as regards oval pipe sheet metal dimensions. A thorough comprehension of the sizes and substances employed will help ensure that the resultant product is of superior quality and meets the requirement.

With many potential applications, from industrial to decorative, oval pipe sheet metal is a popular choice in the fabrication industry. Typically widespread in stainless steel, this material can likewise be crafted from brass, aluminum, copper and other alloys. It’s multifaceted nature and robust construction is making it the go-to choice for creators across all domains.

An oval shape can be achieved with metal by utilizing the process of hydroforming. By applying high-pressure water, the material is formed to the required contours. Whether it is a rounded, oval, square, or triangular shape, this production method is efficient and cost-effective; rendering it an ideal selection for multiple metal manufacturing projects.

Sheet metal dimensions can vary depending on the intended use. Generally speaking, the thickness lies in a range between 0.1 and 0.5 inches, but this can change depending on the context. Rectangular or oval sheet metal could be short and narrow for decorative purposes or longer and wider for a piping construct – it all depends on the requirements of the application.

For metal fabrication purposes, professionals employ various types of oval pipe sheet metals; most commonly, stainless steel due to its enduringness and the absence of corrosion. Lightweight aluminium – though susceptible to corrosion eventually – is a frequent option as it is not arduous to work with in comparison. Other metals, preliminarily copper, bronze and brass, may be further utilised for various reasons; though they are often weaker than stainless steel.

Engaging the right specs for an oval pipe sheet metal project requires consideration of various dimensions – length, width, and thickness. Achieving these specifications is critical for both a tailored appearances as well as long-term performance and quality. Moreover, selecting the appropriate material is paramount in determining the product’s longevity.

Whether utilized as part of a plumbing system or simply a decorative addition, the dimensions of an oval pipe sheet metal may change depending on the purpose it serves. It is vital to consider the necessary specifications of a given application to ensure the product meets all of the criteria it must adhere to.

Manufacturing a quality product requires an understanding of each stage of the process. To start, the correct type of metal gets chosen and shaped into a pipe with a hydroforming machine. Afterward, cutting to the correct length and width is necessary before buffing and refining the edges. Finally, the pipe undergoes a rigorous quality assessment before it is dispatched to the customer.

Quality production starts with familiarizing yourself with the diverse characteristics of oval pipe sheet metal dimensions. Knowing the precise needs of your application and type of material is fundamental for creating products that meet the desired standards. Throughout the manufacturing process, it is essential to guarantee that the pipe is precisely cut and formed to meet all prerequisites. With a comprehensive understanding of oval pipe sheet metal dimensions, you can forge products that are optimized for your application.

Post time: 2023-08-24

Related Product

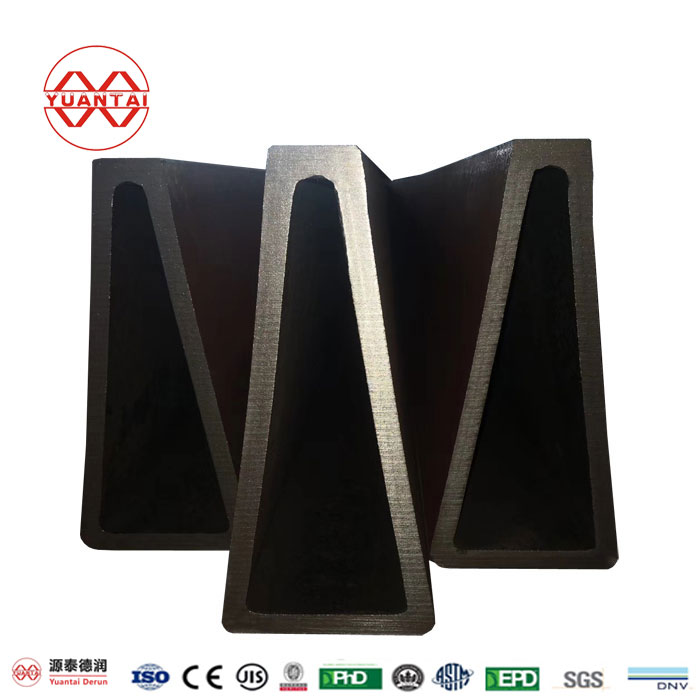

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

Steel Wire Ground Anchor, Fixed Pressure Film Rope For Greenhouse, Ground Anchor, Embedded Part Of Ground Pile For Greenhouse, Steel Wire Ground Anchor

Steel wire ground anchor, fixed pressure film rope for greenhouse, ground anchor, embedded part of ground pile for greenhouse, steel wire ground anchor Steel wire anchor is directl […]

Greenhouse accessories Film roller, super strong side film roller Top windproof film roller

The shell is made of cast aluminum, which is cast by precision die-casting one-time molding process. Its raw materials and casting quality are in sync with the domestic top tier br […]

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]

8-Shaped Steel Pipe

8-shaped steel pipe Product Information Brand: YuantaiDerun Place of Origin: Tianjin, China Alloy Or Not: Non-Alloy Special Pipe: Thick Wall Pipe Standard: ASTMA500/A501/A53,BS1387 […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

Wholesale Hot-Dip Galvanized Oval Pipe Q235B Galvanized Steel Pipe Installation Of Bendable Greenhouse Pipe

The energy-saving solar greenhouse is the most economical and practical greenhouse type among greenhouse types, because this type of greenhouse can be used for winter vegetable cul […]

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]