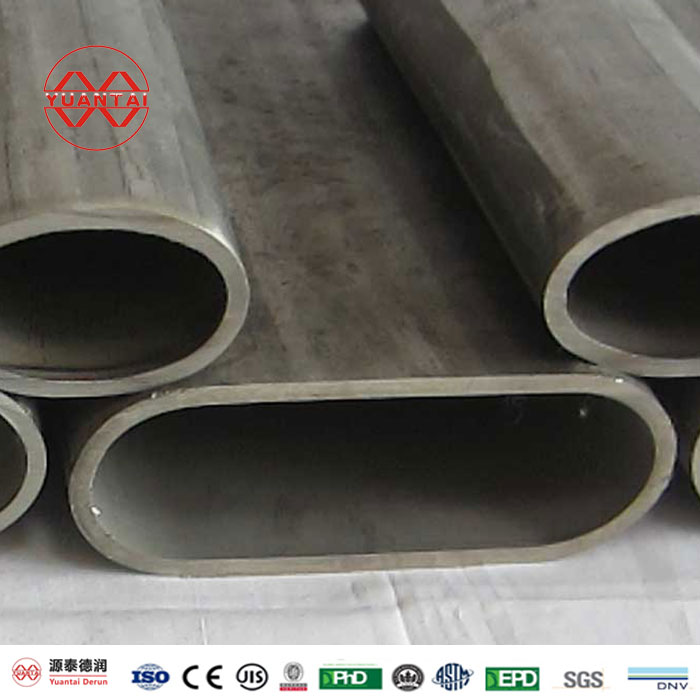

To keep a connection secure between two pipes or valves, an oval pipe flange is used. This specialized pipe fitting is employed not only in plumbing, but also in specialized applications like HVAC and water distribution. Notably, it’s made with a unique shape to make sure that it fits tightly around the joints.

Amongst the various varieties of oval pipe flanges, the butt welded flange is the most ubiquitous. This connection is established between the pipe and flange by welding, making it reliable and able to endure high pressures. While it is certainly a stronger fit, this approach to joining alloy components does come at an extra cost.

Affordably priced yet lacking the resilience resulting from welding, slip-on flanges are ideal for applications where budget is the priority and bolting the pipe to the flange suffices. Though not offering the same pressure rating as a butt welded flange, the convenience of installing a slip-on flange quickly and securely with bolts makes it an appropriate selection in instances when more robust welding is unnecessary.

The size of an oval-shaped pipe flange is determined by the diameter of the fitting it is connected to. More substantial circumference usually correlates with bigger flanges. The many standard sizes available range from 4-inches to 14-inches in diameter. Therefore, the size of the pipe invariably determines its corresponding flange size.

Every flange features a special face type which determines its shape. Two main kinds of face types are the flat face and the raised face. As the more typical choice, the flat face forms a sizable portion of applications. However, for anything requiring higher pressure levels, the raised face is favored to grant additional security.

When it comes to deciding on the size and design of a flange, it is critical to consider two essential aspects: pressure rating and material type. The pressure rating will tell you the flange’s threshold for pressure, while the material type – typically from stainless steel, aluminum, or brass – impacts its durability and might. Keeping these factors in mind will enable to make an informed choice that best suits your needs.

Ensuring the bolts are secured properly is of utmost importance when it comes to fitting an oval pipe flange. An inadequate tightening of the bolts could lead to the fitting being less secure and not meeting its pressure requirements.

When it comes to equipping your plumbing and HVAC gear with sturdy and reliable connections, choosing the correct oval pipe flange is key. This component comes in multiple sizes and forms, all of which should be considered carefully to ensure a secure fit and appropriate pressure rating. Selecting the right flange for the job is necessary in order to guarantee the overall safety and soundness of your systems.

For systems made from pipes, oval pipe flanges are crucial pieces that safely join two pipes together or affix a tube to a vessel, pump, and other things. Offered in an array of measurements and materials, these robust and dependable connectors are essential for proper plumbing.

When looking for the right flange for your project, the dimensions of the oval pipe flange are of utmost importance. The size is determined by the outside diameter (OD) of the pipe and its overall length – bearing in mind that the OD should be measured from the center of the flange and not its external edges. The length is affected by several factors: the OD of the pipe, how many bolt holes are present, and what kind of material is used.

When considering the materials for an oval pipe flange, many choices are available. These range from carbon steel, alloy steel, and stainless steel to aluminum. Although a variety of options are available, it is important to remember that the material utilized impacts the overall strength of the flange and dictates the type of gasket. For example, carbon steel flanges necessitate the use of a flexible gasket like an elastomer or rubber O-ring, whereas stainless steel variants demand a harder metal-based gasket such as copper or bronze.

Generally, the most well-known oval pipe flange dimensions are called standard-sized flanges. These sizes range from 1/2 inch to an impressive 24 inches in outer diameter. The amount of bolts around the periphery of a standard-sized flange vary with the size, rather predictably; a smaller flange would have lesser holes, while a larger one can hold up to twenty four bolts. For example, a 1/2-inch model would generally feature four bolt holes around its circumference, while a 24-inch flange may accommodate up to two dozen bolts or more.

Those who seek flanges beyond traditional dimensions can consider custom-made flanges crafted to their exact specifications. Whatever the needs may be, custom flanges can be fabricated in a wide range of shapes and sizes, from half an inch to 36 inches in diameter, and with any drawn number of bolt holes. Additionally, custom flanges are available in materials like aluminum, stainless steel and nickel-alloy, making them suitable for any niche purpose.

An oval pipe flange can come with a selection of bolt hole sizes, from 1/4 inch to 1/2 inch, all pre-threaded for convenience. Depending on the type of gasket being applied, a larger drill may be required, such as when implementing a metal-based gasket. Furthermore, the number of bolt holes for the flange is determined by its size and the number of pipe sections in the assembly.

To guarantee that you have the right oval pipe flange for your project, it is fundamental to look into the flange’s size, material, and gasket type and size. Moreover, pay special attention to the number of bolt holes as well as their dimensions. When these details are thoroughly evaluated, you can be certain that you have secured the optimal flange for your needs.

Post time: 2023-07-12

Related Product

OVAL TUBE BASE GREENHOUSE ACCESSORIES OVAL TUBE GREENHOUSE CONNECTOR CLAMP

The base of oval tube in greenhouse is no stranger to those who have been exposed to greenhouse equipment. In the installation project of greenhouse equipment, the products of oval […]

Greenhouse accessories Film roller, super strong side film roller Top windproof film roller

The shell is made of cast aluminum, which is cast by precision die-casting one-time molding process. Its raw materials and casting quality are in sync with the domestic top tier br […]

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]

Greenhouse Shed Circlip Dipped Plastic Circlip Manufacturer Wholesale Cartridge Compression Spring Greenhouse Accessories Slot Circlip

Greenhouse shed circlip dipped plastic circlip manufacturer wholesale cartridge compression spring greenhouse accessories slot circlip

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

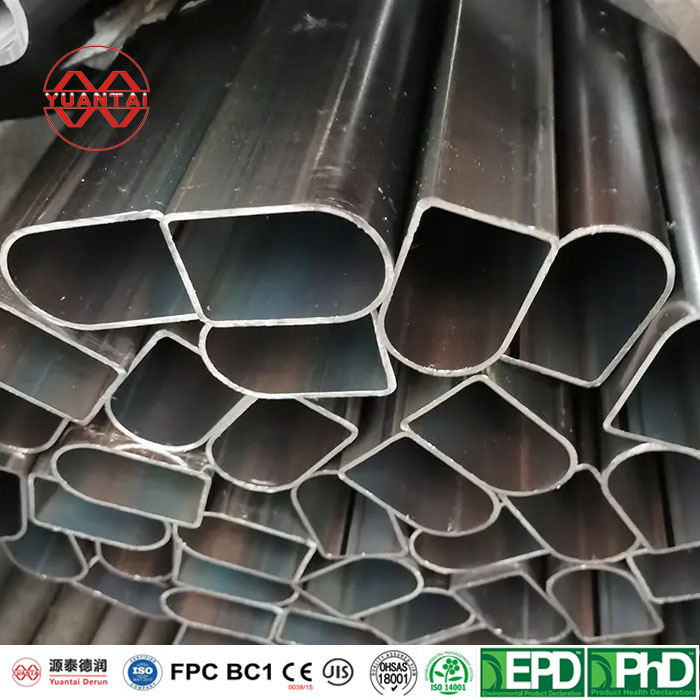

Wholesale Hot-Dip Galvanized Oval Pipe Q235B Galvanized Steel Pipe Installation Of Bendable Greenhouse Pipe

The energy-saving solar greenhouse is the most economical and practical greenhouse type among greenhouse types, because this type of greenhouse can be used for winter vegetable cul […]

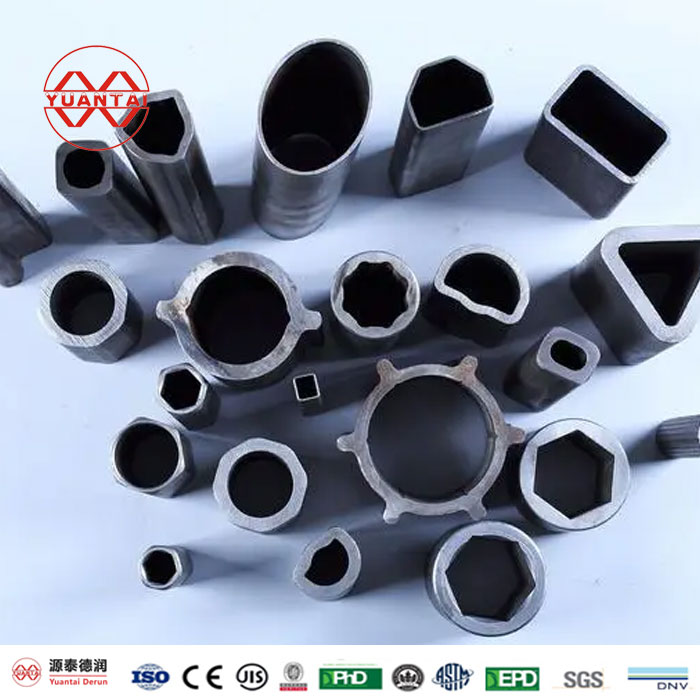

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

Special Shaped Steel Pipe Factory

Special shaped steel pipe factory

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe