For those who feel intimidated by the prospect of cutting steel tubing, fear not – the process is surprisingly straightforward! You may not have to invest in expensive machinery either – there are many tools you can use to cut steel tubing safely and reliably. Here, we will outline some of these tools and techniques for achieving a precise and clean cut every time.

Before starting to slice through steel tubing, it is critical that the tube be measured and a precise cut line be outlined in permanent marker. Ensuring the measurements are accurate is nonnegotiable, as this will allow for the exact cut to be made in the planned spot. Additionally, making sure that the cutting line is smooth and straight allows for an even outcome.

Once the dimensions of the steel tube are documented, it’s time to make the cut. If the size of the tube is small, then a hacksaw is a sensible option as it makes precise cuts down to the millimeter. Plus, it’s relatively inexpensive when compared with a reciprocating saw that also works for larger sizes of tubing. A hacksaw is an indispensable tool for cutting steel and creates cuts that remain true to the desired specifications.

While reciprocating saws boast greater power and are more efficient than a hacksaw, producing more precise cuts in a shorter span of time, what often comes with this added convenience is a greater amount of vibration that could potentially make keeping the cut line straight quite challenging. Such features make them a great option when dealing with larger steel tubes but should be taken into consideration beforehand.

No matter how large or small, cutting steel tubing can be a breeze with the help of a pipe cutter. These handy tools feature a rotating cutting wheel to achieve a clean and accurate cut without any hassle. Efficiency is what makes pipe cutters so attractive; they are designed to provide ease and minimal effort to anyone attempting to slice the steel tubing. Even those who lack experience in cutting such tubing can benefit from its use!

With the right protective gear, you can confidently utilize any tool for your cutting needs. Keep yourself safe by slipping into a pair of goggles, gloves, and a dust mask to shield your eyes and lungs from flying particles that may be produced while you work. Plus, it’s essential to ensure that the tool is safely clamped down for not only enhanced accuracy but also decreased oscillation.

With the right tools and safety procedures in place, it’s time to start on the tubing. Start by taking a steady, methodical approach when cutting along the guideline; doing so will ensure a precise cut. Once complete, use a file or an abrasive, such as sandpaper, to buff away any rough edges and create a smooth finish.

Crafting your ideal cut for steel tubing can be easily accomplished with the correct tools and some basic know-how. Just follow the steps suggested herein and you will land on a precise and safe cutting solution.

Thoroughly preparing a steel tube for construction or manufacturing needs can present a challenge. But if you desire a sleek, sophisticated finish, it’s crucial to invest in the correct tools and techniques. With that said, here are some useful pointers for cutting steel tube successfully, ranging from railings to structural components and project frames.

The right saw and blade are necessary to ensure a precise cut-choose from a metal-cutting circular saw, a chop saw, or for the smaller jobs, an angle grinder with a cut-off wheel. Be sure the blade is designed specifically for cutting metal; wood-cutting blades will not be able to stand up to the strength of the steel and undermine your work.

Prior to beginning, equip yourself with the imperative security gear. A good idea would be to put on safety goggles, gloves and a mask so as to avert the possibility of stray metal fragments colliding with you. Additionally, ensure that your feet and lower body part are covered by opting for closed-toe shoes and full-length trousers. This will act as a barrier between your skin and any sizzling sparks produced from slicing steel.

To ensure your cut is just right, carefully mark out the desired length you would like to cut from your steel tube. Using a permanent marker or other suitable instrument, draw a precise line in order to make the cutting easier and more accurate. This will guarantee an even, tidy cut that meets your specific measurements.

Before you begin to cut the tube, you should take measures to secure it in the right position. This is best achieved by securing the tube with a clamp or by positioning it in a vise. Doing so reduces the risk of the tube moving or being displaced as you cut. To further stabilize the tube, you may want to have a secure platform or table saw ready for use if you are cutting the tube with a circular saw.

When it comes to blade depth, you’ll want to ensure that it aligns with the size of the cut. If you have a circular saw, ensure the blade is set just deep enough to slice through the steel without damaging the saw. For a chop saw, take care to have the blade close to the length of the cut.

When ready, fire up the saw and commence slicing through the steel tube. For circular saws, movement should be steady and unhurried for prevention of any form of stuckness or restriction. As for chop saws, a jerky action is beneficial to efficiently cut away the tubing.

After completing the cutting process, a wire brush and metal file can be used in order to perfectly polish any rough edging, for a stunning outcome.

Through the application of a few guidelines and the right instruments, it is easy to make a cut in steel tubing that appears professionally finished. By utilizing caution and the specified instruments, you can ensure that the cuts look smooth every time.

Post time: 2023-08-18

Related Product

Steel Wire Ground Anchor, Fixed Pressure Film Rope For Greenhouse, Ground Anchor, Embedded Part Of Ground Pile For Greenhouse, Steel Wire Ground Anchor

Steel wire ground anchor, fixed pressure film rope for greenhouse, ground anchor, embedded part of ground pile for greenhouse, steel wire ground anchor Steel wire anchor is directl […]

Wholesale Hot-Dip Galvanized Oval Pipe Q235B Galvanized Steel Pipe Installation Of Bendable Greenhouse Pipe

The energy-saving solar greenhouse is the most economical and practical greenhouse type among greenhouse types, because this type of greenhouse can be used for winter vegetable cul […]

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

OVAL TUBE BASE GREENHOUSE ACCESSORIES OVAL TUBE GREENHOUSE CONNECTOR CLAMP

The base of oval tube in greenhouse is no stranger to those who have been exposed to greenhouse equipment. In the installation project of greenhouse equipment, the products of oval […]

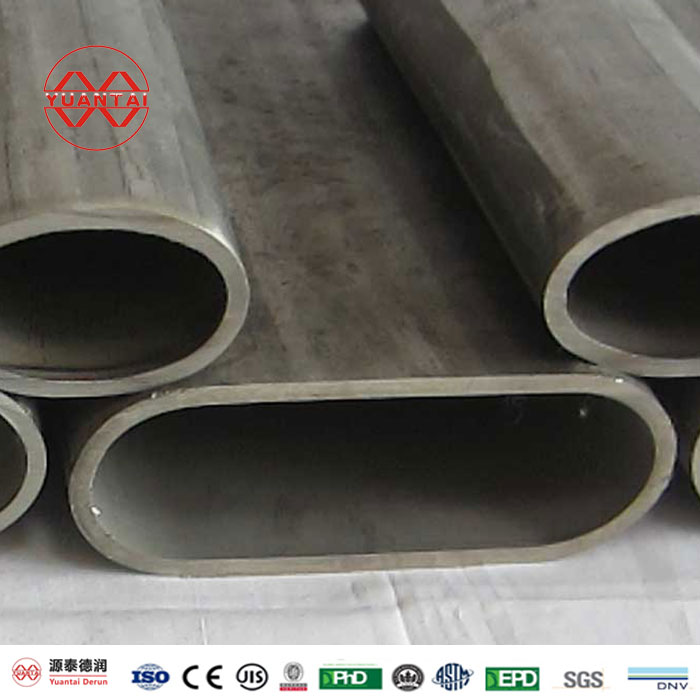

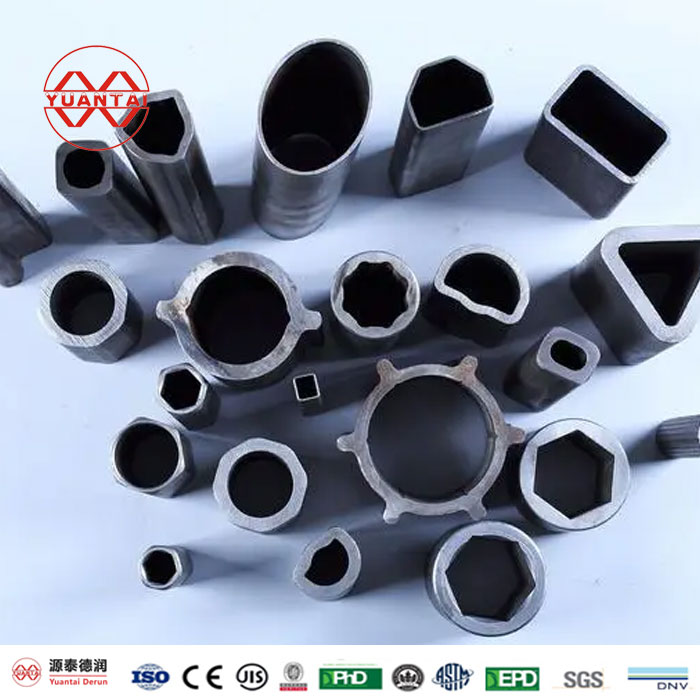

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]

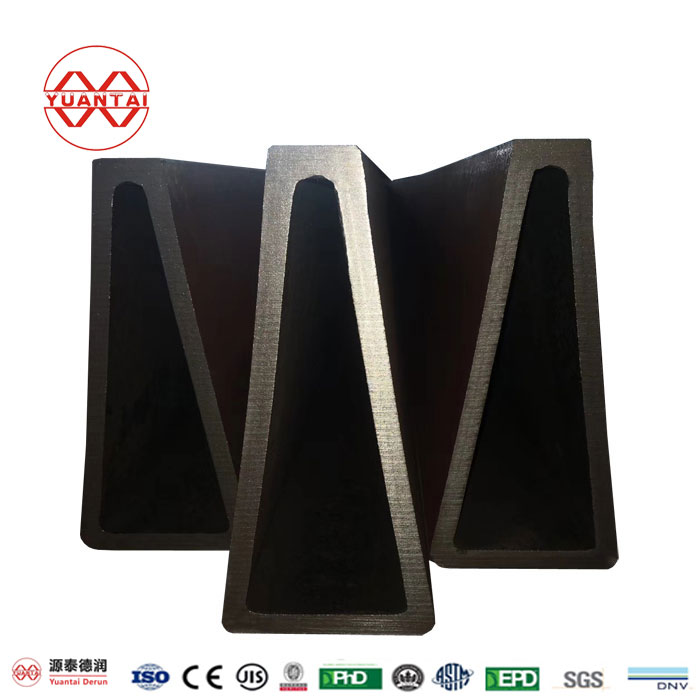

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]

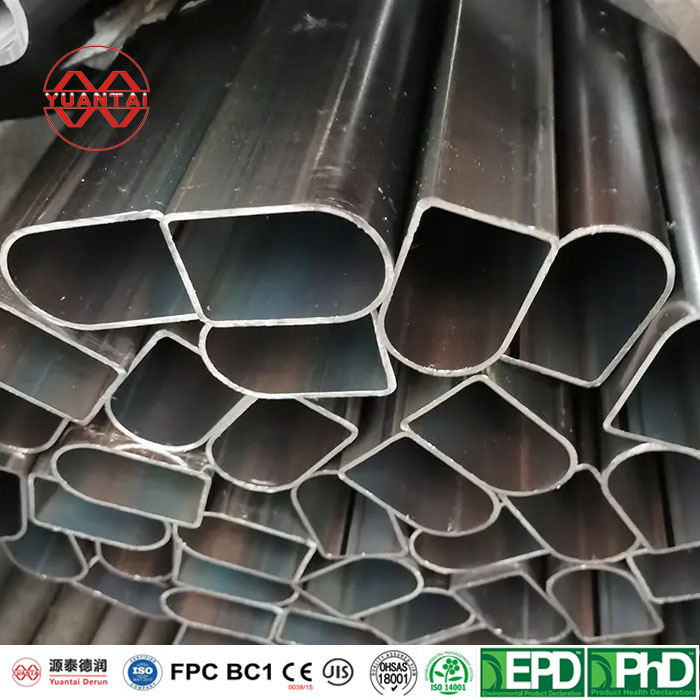

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]