An In-Depth Guide to ERW Steel Tube Specifications

In recent decades, the steel tubes sector has experienced remarkable progress given its numerous applications. Steel tubes have become a sought-after element in automotive, construction, medical, and various industrial projects. Their production is made possible through the assortment of materials used in their manufacturing, for instance carbon steel, alloy steel, stainless steel, and other metals; all of which offer particular qualities beneficial to certain undertakings.

An Electric Resistance Welded (ERW) steel tube is among the most prevalent types of tubes made from steel. This kind of tube enjoys immense popularity owing to its many advantages. Have a look below to be presented with a deep dive into the specifications of ERW steel tubes and their respective applications.

Uncovering the Mystery of ERW Steel Tube

A strong and resilient steel tube is produced through a process of electric resistance welding, otherwise known as ERW. This process involves the creation of the steel tube through cold forming a single metal plate and then welding the edges of the plate together. As a result, a cylindrical tube is formed, making it highly resistant and reliable.

Unlocking the Benefits of Electric Resistance Welded Steel Tubes.

Widely cherished for their numerous benefits, ERW steel tubes provide users with robustness, toughness, and cost-efficiency. Such advantages contribute to why they are so popular amongst industry applications.

ERW steel tubes boast an impressive level of strength due to their unique manufacturing process. Joining the edges together by welding results in an extra-strong and resilient tube that will stand the test of time.

Thanks to the welding process, ERW steel tubes are incredibly robust. The edges are joined together securely, forming a connection that is resistant to wear and tear. This resilience makes the tube able to handle extreme temperatures and other testing weather conditions with no risk of damage.

ERW steel tubes offer maximum savings thanks to their cost-effective production process. Their assembly requires no complicated machinery or expensive tools, making them a budget-friendly choice in comparison to other steel tubes’ on the market.

What do ERW Steel Tubes Have to Offer?

Different types of ERW steel tubes have different specifications. To be more precise, the most widely used ones are:

An array of ERW steel tube diameters are available, ranging from a half inch to an impressive 8 inches. The chosen size will depend on the purpose of its intended utilization.

The wall thickness of ERW steel tubes is flexible and variable, extending from the miniscule 0.5mm to a substantial 12mm. The precise measurement of this dimension is determined by the task it will be utilized for.

The ERW steel tubes offered come in a choice of lengths, providing plenty of options to meet the individual needs of every application. Whatever size is called for, it’s simple to find the ideal fit for your project.

When producing ERW steel tubes, the selection of material can vary, depending on the desired application. Possibilities range from carbon steel to alloy steel to stainless steel, giving designers the flexibility to choose the tube that best fits their project needs.

A wide spectrum of finishes can be applied to ERW steel tubes, from galvanization and black oxide to electroplating. The type of finish is determined by the tube’s intended use in whichever application.

What can ERW Steel Tubes Do for You?

ERW steel tubes have many uses, from automotive to construction. Generally, they are employed to complete the following tasks:

For powering and connecting a vehicle’s crucial elements, ERW steel tubes are employed in the automotive industry. Reasons for their use range from exhausts to fuel supply, as well as brake components.

The construction industry employs ERW steel tubes for a range of integral components, like columns, beams, and trusses. These structures are crucial in sustaining strength and stability in construction projects.

In the world of medicine, ERW steel tubes prove to be indispensable assets, often utilized for instruments and implants needed for medical procedures.

ERW steel tubes are widely used in the industrial domain, utilized for many purposes from housing pressure vessels and boilers to working as heat exchangers.

The remarkable strength, longevity, and affordability of ERW steel tubes make them an ideal choice for many industries. From automobiles and buildings to healthcare and other areas of manufacture, ERW steel tubes of varying specifications can be employed to suit a range of needs. As such, these resilient components are widely employed in the automotive, construction, medical, and industrial fields.

Specifications of Erw Steel Tubes

From furniture components to automotive parts, erw steel tube is massively beneficial for a huge range of applications. Generally, this tube product is crafted from a blend of several metals such as carbon steel, alloy steel, and stainless steel. To ensure you are buying the most suitable erw steel tube for your requirements, it will be essential to consider the associated specifications closely.

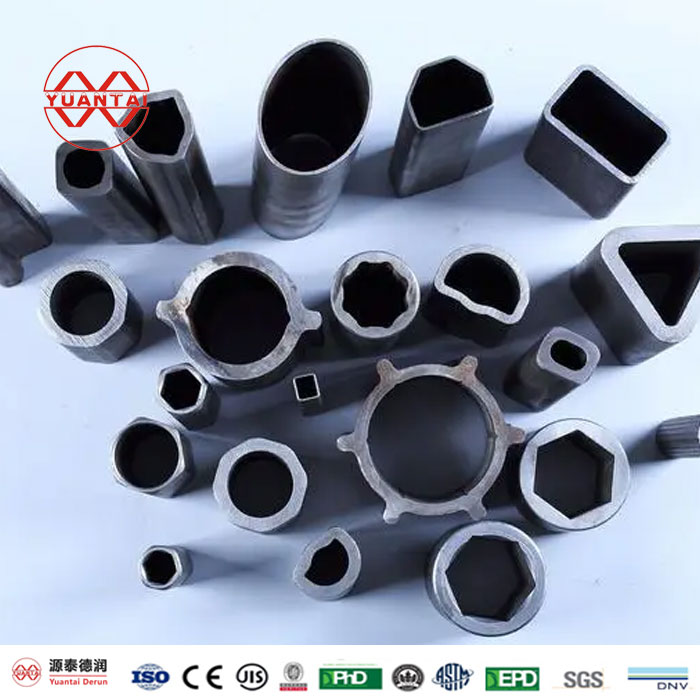

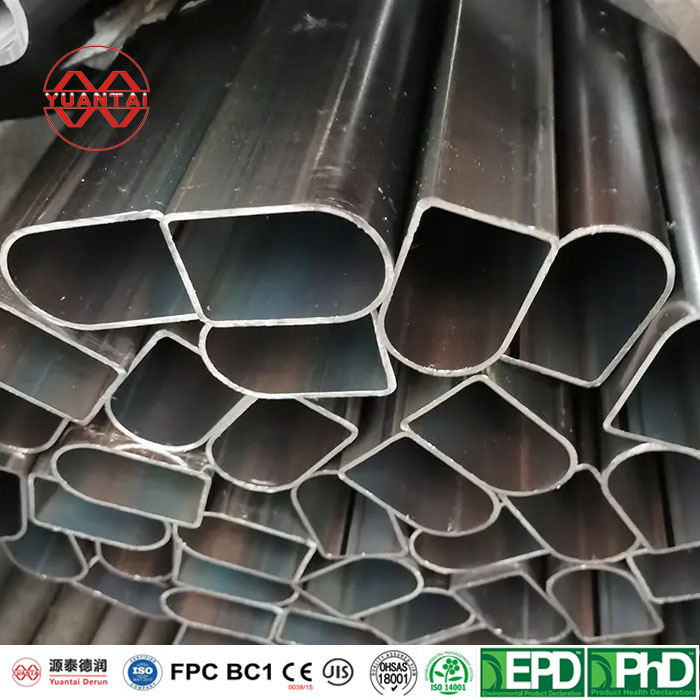

An assortment of shapes and sizes are available when it comes to erw steel tubes. The most commonly seen ones include round, square, rectangular, hexagonal, oval, and octagonal forms. To calculate the size of a tube, its outside diameter and wall thickness need to be assessed. The outside diameter is estimated by gauging one side to the other through the tube. One can determine the wall thickness by measuring from the inside of the tube to its outer surface.

Deciding upon the ultimate substratum used for the production of erw steel tube can differ drastically, dependant on its purpose and practical application. By far the most comprehensive option is carbon steel due to its cost-efficiency as well as sturdy resistance to corrosion. Ultimately, stainless steel and alloy steel may also be taken into consideration based on the situation and requirements of each particular case. It is essential to comprehend the distinguishing characteristics of erw steel tube so that you are able to settle upon an material which is fit for purpose.

Erw steel tubes come in numerous grades, signifying the strength of the material – the higher the grade, the more resilient the tube. Popular grade levels for erw steel tubes are A53, A106, and A500, all of which have distinct standards that must be met in order for it to be used for its intended purpose.

The finish of an erw steel tube is a crucial factor in its ability to remain protected from corrosion and deterioration. It is important to have an understanding of the tube’s specifications when selecting your finish of choice. Popular examples include black, galvanized and painted. These respective coatings are designed to provide a protective shield, thus making sure it is safe from wear and tear.

When assessing the requirements for an erw steel tube, the tolerances must be taken into consideration. These tolerances mark the allowed deviation from the prescribed dimensions of the tube. If the margin of tolerance is too large, there is a risk that the tube will not fit as expected or it could be rendered unable to function to its capacity. Conversely, if the allowances are too strict, manufacturing costs may become excessively high. By assessing all erw steel tube specifications, an optimal level of tolerances can be selected for your application.

To ensure that the erw steel tube meets basic requirements for strength, durability, and safety, there is a need for testing. Testing typically involves tensile tests, hardness tests, and corrosion tests. In order to determine if the tube is suitable for the intended application, it is necessary to review the erw steel tube specifications and understand what kind of tests have already been conducted. Doing so helps you to select an appropriate and high-quality tube.

Erw steel tubes offer a range of advantages, making them a suitable choice for many projects. When shopping for erw steel tubes, it’s essential to familiarize yourself with the various specifications so that you can pick the item best suited to your requirements. Becoming familiar with erw steel tube specifics means you can make sure you’re purchasing something capable of standing up to the rigors of whatever application it is employed in.

Post time: 2023-08-19

Related Product

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

Greenhouse Shed Circlip Dipped Plastic Circlip Manufacturer Wholesale Cartridge Compression Spring Greenhouse Accessories Slot Circlip

Greenhouse shed circlip dipped plastic circlip manufacturer wholesale cartridge compression spring greenhouse accessories slot circlip

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]

Octagonal Steel Pipe

Tianjin Yuantai Derun Group has 18 wholly-owned subsidiaries, of which Tianjin Yuantai Technology Development Co., Ltd. was founded in 2014 to produce super large diameter, super t […]

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

Steel Wire Ground Anchor, Fixed Pressure Film Rope For Greenhouse, Ground Anchor, Embedded Part Of Ground Pile For Greenhouse, Steel Wire Ground Anchor

Steel wire ground anchor, fixed pressure film rope for greenhouse, ground anchor, embedded part of ground pile for greenhouse, steel wire ground anchor Steel wire anchor is directl […]

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]