There are certain standards and regulations to consider when selecting a corten steel tube size for a specific application. Size selection may depend on the producer, the project requirements, and its goal. Nonetheless, there are some ground rules that can help one narrow down their choice of size.

Structural applications call for tubes that are able to withstand the force of the loads applied to them, making it essential to select a larger size. On the other hand, for projects that require a decorative touch, it is better to go with a smaller size to achieve the desired visual effect.

A key aspect to mull over when picking the size of a corten steel tube is its thickness. Patrons will discover thicker constituents will be significantly tougher and better suited to withstanding rigors of everyday wear and tear, while the thinner options are more resilient and convenient to manipulate.

After the appropriate size and thickness have been organized, the later step would be to approximate the length of the tube. This can be done by taking notice of the area which requires the tube to be placed in and picking out the maximum length that can be accommodated within that region.

Having established the size of the tube, the next criteria is its width. Based on the goal for which it is being used, one must pick a width accordingly. If the tube is meant to serve a structural purpose, then choosing a broader tube would be preferable; if it has more of a decorative significance, then building with a slim variety would be more effective.

Once the parameters for size, depth, length, and width are determined, the subsequent decision should be one of wall thickness. The best option for any given application depends entirely on the purpose of the tube. If structural support is sought, a thicker wall works best; however, if aesthetics are paramount, a thinner wall will fit the bill.

After the wall thickness has been chosen, the following task is to figure out how many tubes will be essential. This can be ascertained by computing the total space that the tubes will envelop.

To decide upon the right finish for your chosen product, first identify its intended purpose. A tube requiring structural strength will need resilient coating, while more decorative projects will benefit from an eye-catching finish. Simply select the finish that best suits your project’s requirements.

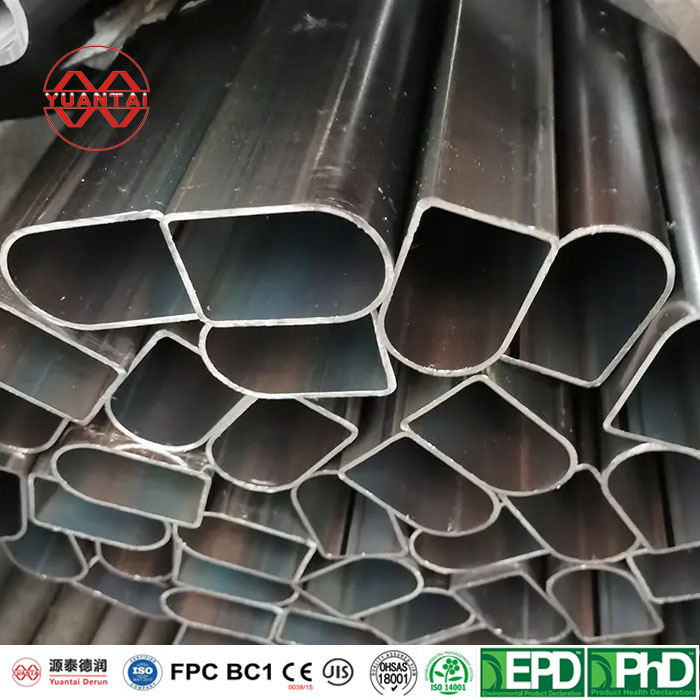

Once a suitable finish has been decided upon, the process of choosing an adequate tube-shape can commence. While round, square, and rectangular are the most common forms of tubing, there are plenty of other options available for selection.

After the ideal form has been decided, the second task is to evaluate how long the tube needs to be. This can be figured out by ascertaining the confined area where the tube will reside and selecting the longest accessible length that fits within.

Once the size has been decided upon, the next decision in the process is to choose a breadth. The width should be mindful of the purpose of the tube. For instance, broader pipes would suit structural applications better, whereas narrower variants would be ideal for decorative purposes.

Having chosen the desired width, it’s time to focus on wall thickness. Consider the purpose of the tube: if it is to fulfill a structural requirement, opt for robust walls; whereas if aesthetics are more important, then thinner walls will do the trick.

Upon selecting a specific wall thickness, the subsequent step is to determine how many tubes will be needed in order to cover the overall area in question. This can be done by reckoning the total space that these tubes will be enveloping.

With the dimensions of the tubes established, it is then necessary to choose the suitable type of finish. Depending upon the desired usage of the tube, a stronger finish might be required for structural roles, while a visually appealing finish could be ideal for ornamental purposes.

After deciding on a finish, determining the desired tube shape is the next step. Popular options include round, square, and rectangular forms, yet one can also select from additional unconventional designs.

The initial selection of the shape finalized, the natural progression is to assess the length of the tube desired. Inspecting where the tube will be located provides the information needed to identify a length that fits perfectly within that specific area.

With the desired length established, attentions must then turn to the width of the tube. This assortment should be determined according to intended usage; tubes of a larger proportions are most conducive to structural application, while thinner tubes work best for decorative purposes.

Upon deciding on the width, picking an appropriate wall thickness follows. Wall thickness should align with the purpose of the tube – thicker walls will challenge structural applications while thin walls will be more convenient for decorative ones.

After choosing the desired wall thickness, the next step is to calculate how many tubes will be necessary for the project. This can be determined by ascertaining the total area that must be covered. Once this figure has been calculated, one can factor in the diameter of the tubes with the predetermined wall thickness to determine the number of tubes needed.

Post time: 2023-06-28

Related Product

8-Shaped Steel Pipe

8-shaped steel pipe Product Information Brand: YuantaiDerun Place of Origin: Tianjin, China Alloy Or Not: Non-Alloy Special Pipe: Thick Wall Pipe Standard: ASTMA500/A501/A53,BS1387 […]

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

OVAL TUBE BASE GREENHOUSE ACCESSORIES OVAL TUBE GREENHOUSE CONNECTOR CLAMP

The base of oval tube in greenhouse is no stranger to those who have been exposed to greenhouse equipment. In the installation project of greenhouse equipment, the products of oval […]

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]

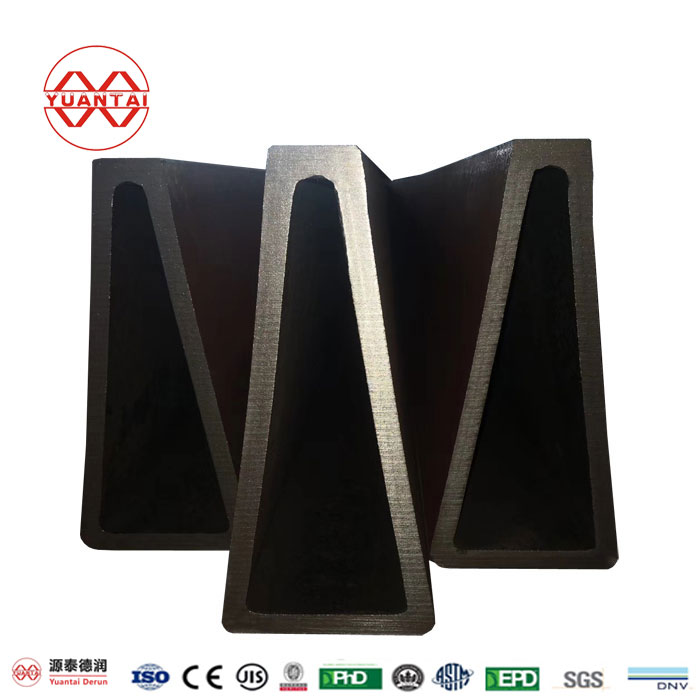

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

Supply Of Zigzag Steel Clips New Type Of Zigzag Steel Framework Connecting Clips

Product name: Jizi steel skeleton accessories Product alias: zigzag steel card, zigzag steel bending connection Product description: The framework of the shed is made of zigzag ste […]