The Coal Mining Steel Tube Return Roller is no small detail – it’s an indispensable piece of equipment within mine structure. This roller works to help maneuver heavy duty machinery and thus plays an integral role in the safety and efficiency of mining operations. Its importance must not be overlooked as it improves a mine’s structure with its sturdy and reliable design.

An integral part of any coal mining operation, the steel tube return roller is tasked with keeping the conveyor belt firmly placed and safeguarded against potentially debilitating damage. Beyond that, it is also employed to ensure that the belt is able to reset itself along its original trajectory after having been utilized. Therefore, stability and reliability are two of the most prominent characteristics that define the importance of this component.

To provide a seamless, low-friction movement of the conveyor belt, a return roller is constructed with a steel tube as its core. This tube is filled with a specialized bearing that reduces the amount of force needed for the roller to rotate and for the belt to travel. Offering an extra layer of protection, a rubber or plastic material is fitted around the steel cylinder to guard it from any impending harm.

In the subterranean mining environment, return rollers are an essential piece of machinery that helps keep operations running smoothly. By utilizing this component, the longevity of the conveyor belt is extended and overall efficiency is heightened. Return rollers also minimize vibrations and promote a safer working atmosphere by providing stability for the conveyor belt. This ensures that processes run in an optimal manner with minimal down-time.

The return roller is a beneficial addition to any conveyor belt, as it assists in keeping the mechanism moving in the expected direction, helping to save it from any wayward pitfalls. This is of particular relevance within the underground mining sector, where its use can keep everyone safe by preventing any potential injury to miners as well as eliminating any potential damage to the conveyor belt.

The roller serves a critical purpose in cutting down the energy that is integral to powering the conveyor belt. By diminishing the friction between the conveyor belt and the surface below, the roller helps to minimize the amount of energy required to keep the belt moving.

The steel tube return roller proves to be a valuable asset for many coal mining operations due to its unrivaled ability to ensure conveyor belt stability and reduce energy expenditure in terms of movement. Superior return roller quality not only keeps the conveyor belt running at peak performance, but helps protect miners on the job from potential risks. Investing in a top-of-the-line return roller is a great way to enhance efficiency in operations and provide safe, reliable service.

As a vital component in ensuring coal mining efficiency and safety, Steel Tube Return Rollers are essential hardware for the successful operation of underground coal mining. By providing reliable support and a sustained system of movement for haulage equipment, these roller wheels ensure that the conveyor belt runs both smoothly and continually during coal harvesting activities. Moreover, these components also reinforce the structural integrity of coal mine systems around the world through specialized optimization techniques such as increased bearing capacity which allows for an enhanced level of system carrying having a direct impact on safety and productivity.

The rugged world of coal mining calls for reliable equipment that is up to the challenge. This is why the steel tube return roller holds such a vital place in mining operations. Nothing compares to its ability to provide support and safety as miners navigate the physical risks of working underground – where cave-ins, dangerous gases, and heavy machinery abound. Such are the extreme hazards of a coal miner’s everyday work environment.

A return roller made of steel is a necessary devise for successful coal mining. This cylindrical roller uses its steely form to help guide the coal-flexing conveyor belt back to its original placement. Without the return roller, mining these dark depths would be an adventure of impossibility as it secures the belt on its track – allowing coal to traverse long distances from its harvest point.

The return roller plays a vital role in the coal mining process. It provides support for the conveyor belt, helping decrease the risk of unexpected slips and associated delays that could hinder productivity. By remaining in place, the return roller also serves to minimize corrosion and wear on the conveyor so that it can remain functional for extended periods of time. Ultimately, this encourages the mine to run smoothly and more efficiently.

When it comes to coal mining, return rollers are a must. No matter the size or shape, steel tube return rollers are the preferred choice for operational applications due to their unparalleled durability and robustness. What’s more, they require minimal attention over their long lifespans, meaning you can spend more time on other important aspects of your mine.

Steel tube return rollers are not just dependable and low-maintenance but have several other advantages. Weighing relatively less and being easy to mount, they are the go-to solution for places with limited space and faraway settings where it could be bothersome to fit larger rollers. Moreover, as they boast rust-protection, they are bound to serve you longer and need less choosing replacement.

Dependable and easy to maintain, return rollers made from steel tubing prove to be an invaluable asset in coal mining. Lightweight and simple to install, they can even be set up in the most out-of-the-way places. When high quality rollers are procured by the owners of a mining operation, not only is overall efficiency boosted, but they also can be certain that their machinery will remain reliable and secure.

Post time: 2023-08-13

Related Product

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

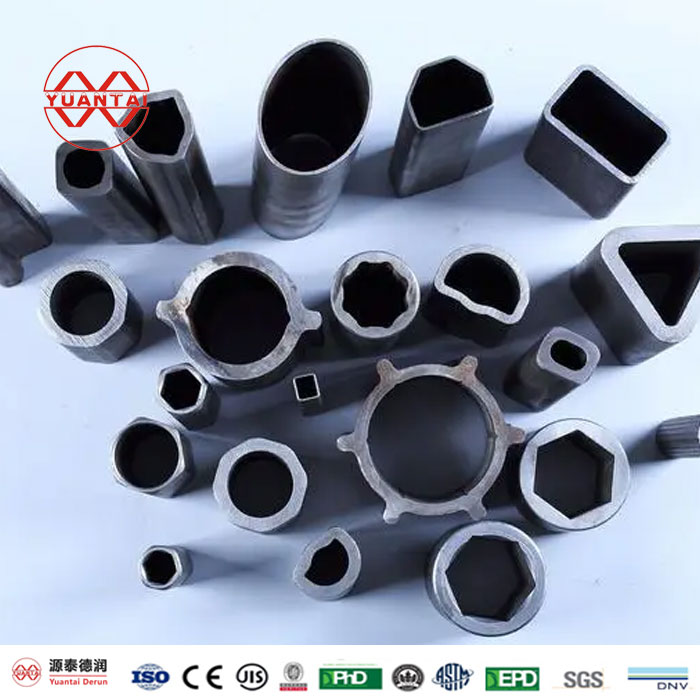

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

Octagonal Steel Pipe

Tianjin Yuantai Derun Group has 18 wholly-owned subsidiaries, of which Tianjin Yuantai Technology Development Co., Ltd. was founded in 2014 to produce super large diameter, super t […]

OVAL TUBE BASE GREENHOUSE ACCESSORIES OVAL TUBE GREENHOUSE CONNECTOR CLAMP

The base of oval tube in greenhouse is no stranger to those who have been exposed to greenhouse equipment. In the installation project of greenhouse equipment, the products of oval […]

Steel Wire Ground Anchor, Fixed Pressure Film Rope For Greenhouse, Ground Anchor, Embedded Part Of Ground Pile For Greenhouse, Steel Wire Ground Anchor

Steel wire ground anchor, fixed pressure film rope for greenhouse, ground anchor, embedded part of ground pile for greenhouse, steel wire ground anchor Steel wire anchor is directl […]

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]