Exploring the Properties of Black Annealed Square Steel Tube

Square steel tubes are an integral part of everyday life, with their existence spanning a multitude of industries such as plumbing, automotive, and even aerospace. However, one of the most commonly employed types of square steel tubes is the black annealing square steel tube. Making a name for itself with its excellent aesthetic qualities and high level of resistance to wear and tear, this particular variety deserves further examination. In this article, we explore why the black annealing square steel tube is so sought after.

Unveiling the Mystery of Black Annealing Square Steel Tube

To grant a heightened surface element and a rich black hued finish, black annealing may be applied to square steel tubes. This process increases the resilience and fortitude of the steel tubes, as well as making them impervious to erosion. Black annealing is regularly employed for square steel tubes due to its aesthetic appeal compared to other methods of annealing.

Advantages of Carbonizing Square Steel Tube with Black Annealing

Square steel tube crafted via black annealing boosts lifespan, strength, and visuals. Its improved resilience keeps it from succumbing to wear and tear, and its bolstered integrity prevents corrosion more effectively. Aesthetically speaking, this steel tube type offers an appealing finish compared to other versions.

Those in search of a budget-friendly annealing method need look no further than black annealing for square steel tube. This process is notably more economical than alternative approaches, plus it yields a black finish that offers greater versatility for all kinds of projects. An ideal solution for those with restrictive financial boundaries, black annealing can really help get the job done without breaking the bank.

Utilization of Square Steel Tube through Black Annealing

With its strength and corrosion resistance, square steel tube with a black annealing finish serves many needs across different industries. Construction, plumbing, and automotive fields all benefit from its sturdiness and durability. Additionally, it adds a unique aesthetic feel to furniture and other decorative items, creating a modern look. Similarly, it proves to be advantageous even in industrial applications where it has the capacity to withstanding heavy wear-and-tear for extended periods of time.

Ultimately, black annealing square steel tubing presents an attractive, resilient, and cost-effective option for a wide array of industries. From construction and plumbers to automotive and aerospace, this form of steel tubing is highly sought-after for its robustness and multi-purpose aesthetic. Moreover, this steel tubing can be treated with a black annealing process which is both affordable and offers a vast array of possibilities for its utilization.

Steel tube manufacturing has relied on the black annealing process for decades. This efficient, effective process creates strong and durable square steel tubes and has been a go-to option for manufacturers seeking reliable outcomes. In this piece, we will explore the efficaciousness of black annealing in the realm of square steel tube production and outline some of its many advantages.

Reaching a sizzling high temperature in an oxygen-deprived chamber, the black annealing process begins. This draws out any risk of oxidation or accumulation of a scale, while enabling the steel to heat consistently. Subsequently, the steel is retarded at a slow rate, allowing carbon and other components to integrate into the structure of the metal substance. This potent technique infuses durability into the steel; ultimately, making it ideal for producing square steel tubes that boast higher strength and resilience levels.

High levels of carbon give the steel produced by the black annealing process its distinct dark color. This touch of black not only adds an aesthetic element to the steel, it also provides a strong barrier against corrosion and deterioration over time. This process of black annealing also expedites the manufacturing process involved in creating square steel tubes.

The advantage of black annealing is its capacity to deliver a consistent outcome. The reason being the slothful cooling practice, supporting the achieving of an even temperature through the steel. This steers to a uniform cylinder wall strength and thickness, offering a sold product.

Through the black annealing methodology, each steel tube is cooked to perfection. The phased-out cooling procedure ensures the alloy is uniformly heated, measuring out the carbon and other elements within to exact specifications. This leads to a top-notch end product that surpasses ordinary steel-making procedures.

By opting for the black annealing technique, producers of square steel tubes dramatically reduce their production costs and time frame. The cooling process, though slower in comparison to other annealing techniques, is a cost-effective solution to achieve quick and economical manufacturing outcomes.

All things considered, black annealing is an attractive option to generate strong, long-lasting square steel tubes. It offers a consistent, high-quality output which is also very cost-efficient, making it a preferred choice for many manufacturers.

Post time: 2023-07-14

Related Product

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

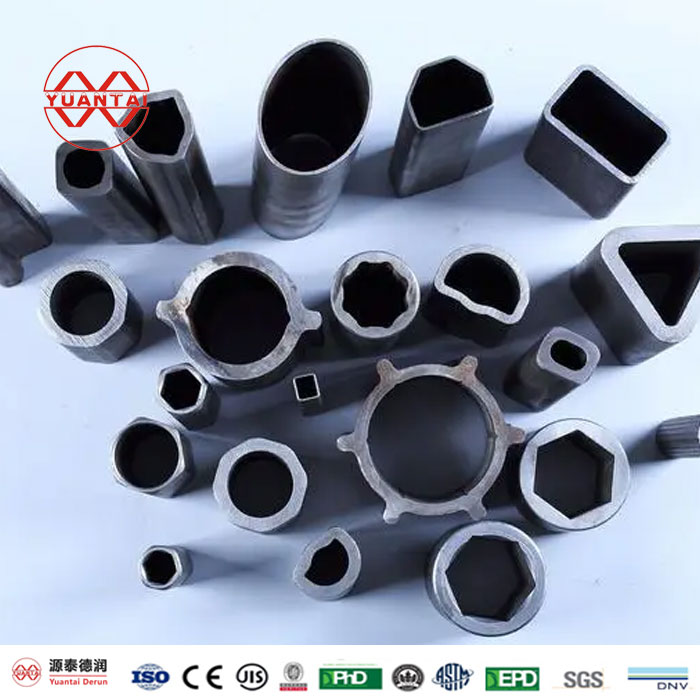

Six Angle Steel Tube,Hexagon Steel Pipe Outer Six Inner Circular Special-Shaped Steel Pipe

Hexagonal steel pipe is also called special-shaped steel pipe, including octagonal pipe, rhombic pipe, elliptical pipe and other shapes. It is an economic section steel pipe, inclu […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

OVAL TUBE BASE GREENHOUSE ACCESSORIES OVAL TUBE GREENHOUSE CONNECTOR CLAMP

The base of oval tube in greenhouse is no stranger to those who have been exposed to greenhouse equipment. In the installation project of greenhouse equipment, the products of oval […]

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]

Steel Wire Ground Anchor, Fixed Pressure Film Rope For Greenhouse, Ground Anchor, Embedded Part Of Ground Pile For Greenhouse, Steel Wire Ground Anchor

Steel wire ground anchor, fixed pressure film rope for greenhouse, ground anchor, embedded part of ground pile for greenhouse, steel wire ground anchor Steel wire anchor is directl […]

Special Shaped Steel Pipe Factory

Special shaped steel pipe factory