Tubular steel is a popular choice for many kinds of construction projects; from building furniture and structures to creating complex components. It offers robustness, versatility, and affordability, making it an ideal material for a wide range of industrial applications. However, it can be challenging to accurately cut and shape tubular steel due to the specialized tools and techniques its manipulation requires. Here, we will talk about how best to cut tube steel with precision and ease.

When it comes to cutting tube steel, selecting the correct tool for the job is of paramount importance. Several options are on offer, such as hacksaws, metal-cutting band saws, and circular saws, each boasting their own unique benefits and drawbacks. When deciding which to utilize, one must analyze the type of material they are handling and the desired outcome in order to make an informed choice. If you’re dealing with thin-walled tube steel, hacksaws are ideal, while if you’re working with thicker materials then metal-cutting band saws are more suitable.

Once you’ve identified the right tool to get the job done, it’s time to ready the tube steel for slicing. Setting it up is key for guaranteeing a perfectly accurate and precise cut. Therefore, measure and mark the tube steelat the particular point of division using a ruler, pencil, or marker. It is also important to use a razor-sharp blade for cutting tube steel, as this will make sure that the cut is clean-cut.

If you want to cut tube steel properly, there are various possibilities to choose from. One of these is the hacksaw, but when using it, it’s important to remember to saw slowly and steadily in order to avoid problems like blade slipping or material damage. When dealing with thicker pieces of steel, a metal-cutting band saw is certainly the better option, and in this case speed should be reduced even further for clean, accurate cuts.

For an extra touch of precision, grab yourself a cutting guide. This handy addition attaches to your material and takes over the heavy lifting, keeping your blade steadily in place to give you a perfectly even and precise cut each time.

When working with tube steel, it’s prudent to ensure your own safety. Protective eyewear and gloves are essential, as the edges of the metal will be razor sharp when cut. Additionally, it is important to maintain a neat workspace to reduce potential safety hazards posed by loose debris in the area.

Ultimately, slicing tube steel can be a physically demanding and time-consuming job, yet when done with the correct tools, methods and safety precautions, it can be handled rapidly and precisely. Before you start, ensure that you have done the necessary research and always put on the necessary safety gear.

When it comes to working with tube steel, the right cut can make all the difference. To ensure your end product meets your expectations, review the different ways to effectively trim the steel below. We also share some expert advice so you can tackle the task with success!

When it comes to slicing tube steel, the technique you choose is dependent on the material at hand, the dimensions of the tube, and how precision is required. Many techniques may be employed in the endeavor, so let’s take a peek at some of the more commonplace approaches.

Hacking with a Hacksaw

For an easy and efficient approach to cutting most kinds of tube steel, the hacksaw’s your go-to. Sharpening the blade and getting rid of any burrs beforehand is absolutely essential for this job, so make sure that’s done properly. To use it, secure your tube to a vice and double-check all your work – no-one wants a wobbly cut. Then just take slow, steady strokes and you’ll have the end result in no time.

Appropriately Slicing with a Tubing Cutter

If you’re looking for a fast and precise way to cut tube steel, then look no further than a tubing cutter. It securely clamps the tube in a vice, then uses a revolving sharp blade to cut through in no time. With different sizes available, make sure to select the one that’s appropriate for your project – it’s a fantastic option especially if you have a sizable job at hand.

Harnessing the Power of a Grinder for Cuts

Tube steel can be transformed into the desired shape or size for any large-scale project with the magnificent power of a grinder. To start, ensure that the steel is adjoined inside a vice and held in place firmly. Utilize a grinding wheel to sharpen through the tube as needs be. Industrial operations often utilize this efficient method as it can cut accurately and swiftly.

Utilizing a Plasma Cutter for Trimming

Working on larger projects? A plasma cutter is precisely what you need. Utilizing a blast of hot plasma, these high-powered tools are ideal for efficiently and accurately cutting through metal. To begin, secure the tube in a vice and ensure it is firmly clamped in place. Then you can wield the plasma cutting tip to slicing through your tube steel. The perfect solution for those industrial-level projects!

Reap Perfection with a Band Saw

With the sheer power of a band saw, it is possible to create precise cuts on larger metal projects with remarkable speed. This type of saw is often chosen in industrial settings and requires that the tube steel be firmly secured in a vice before use. A continuous band saw blade is then employed to slice through the metal across its continuum.

Chopping with a Chilly Chop Saw

When tackling bigger projects, using a cold saw is often the best choice. Able to cut efficiently and precisely, this specialized device utilizes a high-velocity blade to swiftly slice through metal elements. If utilizing a cold saw, be sure the material being cut is held tight in a vice. Doing so will guarantee that the tube steel is stable while the cold saw blade does its work.

Techniques for Slicing Tube Steel

If you want to have success when cutting tube steel, make sure to incorporate these tips. Securing the tube in a vice is essential for a precise cut. Additionally, check that your tools are both sharp and free of debris; otherwise, it can be difficult to get an accurate cut. Finally, use slow and steady strokes for the same purpose. A longer stroke can help ensure an even and clean end product.

To master the art of cutting tube steel, you need to be both a pro at precision and have the right tools for the job. This article aims to provide an overview of the most productive methods for cutting tube steel, as well as helpful advice for a successful cut each time. When opting for a hacksaw, tubing cutter, grinder, plasma cutter, band saw, or cold saw, ensure the instruments you choose are sharp and free from any chips. Furthermore, taking slow and measured strokes in the process will ensure an accurate cut straight away.

Post time: 2023-07-05

Related Product

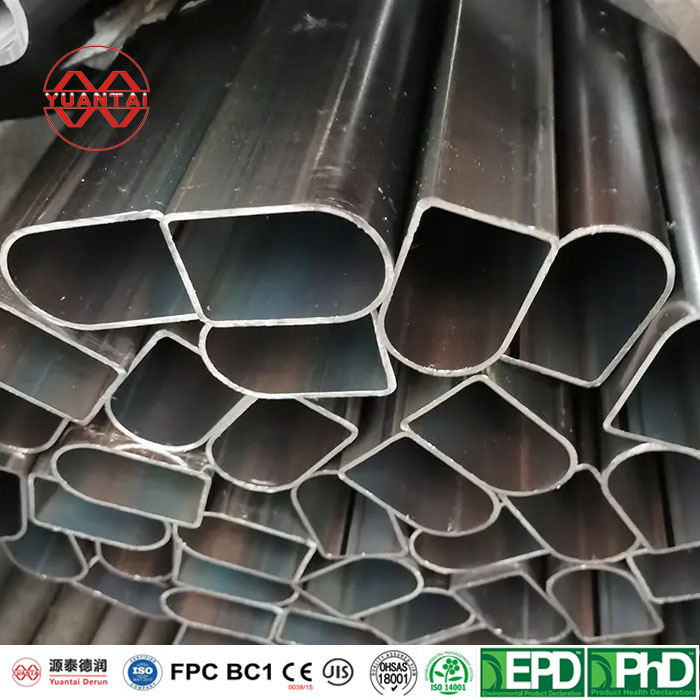

Octagonal Steel Pipe

Tianjin Yuantai Derun Group has 18 wholly-owned subsidiaries, of which Tianjin Yuantai Technology Development Co., Ltd. was founded in 2014 to produce super large diameter, super t […]

OVAL TUBE BASE GREENHOUSE ACCESSORIES OVAL TUBE GREENHOUSE CONNECTOR CLAMP

The base of oval tube in greenhouse is no stranger to those who have been exposed to greenhouse equipment. In the installation project of greenhouse equipment, the products of oval […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

Greenhouse Shed Circlip Dipped Plastic Circlip Manufacturer Wholesale Cartridge Compression Spring Greenhouse Accessories Slot Circlip

Greenhouse shed circlip dipped plastic circlip manufacturer wholesale cartridge compression spring greenhouse accessories slot circlip

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

Greenhouse accessories Film roller, super strong side film roller Top windproof film roller

The shell is made of cast aluminum, which is cast by precision die-casting one-time molding process. Its raw materials and casting quality are in sync with the domestic top tier br […]

Steel Spiral Ground Pile

Steel spiral pile is the most widely used one. The steel spiral pile is very suitable for practical production in terms of technical indicators and economy, and can be recommended […]