Harnessing Heat to Realign Steel Tube

Steel holds a place of esteem in the manufacturing and construction industries, backed by its strength, durability, and versatility across applications. Its malleability makes it possible to mold the material into various forms and configurations. Straightening is an integral part of the design process which involves bending and reforming steel until its edges are laser-straight.

Straightening steel calls for considerable attention, and heat is typically the most popular approach. Flame heating, resistance heating, and induction heating are all available options, each with its own strengths and drawbacks.

Electric current is sent through a coil that encases the steel tube during induction heating, causing the steel to rapidly heat up. This renders it malleable and simpler to shape. One of the drawbacks of this process, however, is that it is both costly and time-consuming.

With flame heating, straightening steel tube is a breeze. Using a gas flame, the tube is evenly heated until it becomes malleable. This approach to steelwork is swift and cost-effective – though heat control can prove challenging.

By applying an electric current to a tube of steel, the Resistance heating process permits the metal to become pliable. A speedy and cost-effective process, it can be arduous to maintain the consistency and accuracy of the temperature.

Heating the steel brings it to the correct temperature for shaping. Straightening of the steel tube may be executed manually by using a hammer and anvil, requiring considerable effort as well as substantial time. Although manual straightening is a viable option, machinery can also be employed for the job.

To bend steel tubes into desired shapes, specialized devices such as rollers, presses, or straightening tools can be employed for the task. This method of machine straightening is far more precise and efficient than manual straightening; however, this process can be costly due to the cost of obtaining the necessary machinery.

When tackling steel tubes, safety should be of utmost priority. Somebody partaking in the activity should be suited up in safety gear such as gloves, glasses, and a face mask. Moreover, to ensure the area is not filled with any dangerous fumes, a well-ventilated space is highly recommended.

When it comes to any steel fabrication job, proper alignment of steel tubing is absolutely essential; for this, numerous ways of shaping the tubes depending on the cost, safety requirements and time available can be utilized. The process of heating the tube straightening is, therefore, indispensable. Each option presents its own trademark features as well as drawbacks; for that reason, one must take into consideration all of these aspects prior to deciding which one will best suit your project.

Heat straightening steel tubes is an easy-to-use, budget-friendly approach to counter the warping flairup from thermal extension, welding activities and other environmental triggers. This process is employed in the automotive, construction and manufacturing sectors given its limitless usage potential. This efficient solution guarantees that steel tubes necessarily stand up for a range of applications.

Choosing the right steel tubing for the desired application entails substantial consideration. After the selection has been made, it is then heated to the appropriate temperature depending on the type of steel. Mild steel, for example, must be heated to a range of 500 to 800 degrees Fahrenheit while harder steels require greater heat levels (850 – 1100F). Once these conditions are reached, the straightening of the steel tube can begin.

After heating the steel tubing, it is secured in a straightening jig meant to hold it in position. This device is composed of two adjustable clamps placed at each end. By correctly adjusting the clamps, the tubing is firmly clamped in place. With this done, the jig can be gradually moved along the tube, exerting enough pressure to force the material into a straightened state.

Moving cautiously, the jig traverses the tubing, applying pressure where necessary for straightening. After the jig has traveled the entire length of the tubing it is cooled. Ensuring that the tubing is properly cooled before removal from the jig is essential – any lingering heat can cause the tubing to bend and contort upon removal.

To make sure steel tubing is fitted suitably for a variety of applications, heat-straightening proves to be a prudent course of action. This approach is user-friendly, economical, and productive in making certain that the steel tubing yields maximum utilization. Often applied in construction, carmaking, and manufacturing, heat straightening is proficient at eluding the warping and twisting caused by thermal enlargement, union, and other exterior pressures.

Post time: 2023-07-06

Related Product

Steel Wire Ground Anchor, Fixed Pressure Film Rope For Greenhouse, Ground Anchor, Embedded Part Of Ground Pile For Greenhouse, Steel Wire Ground Anchor

Steel wire ground anchor, fixed pressure film rope for greenhouse, ground anchor, embedded part of ground pile for greenhouse, steel wire ground anchor Steel wire anchor is directl […]

Greenhouse accessories Film roller, super strong side film roller Top windproof film roller

The shell is made of cast aluminum, which is cast by precision die-casting one-time molding process. Its raw materials and casting quality are in sync with the domestic top tier br […]

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

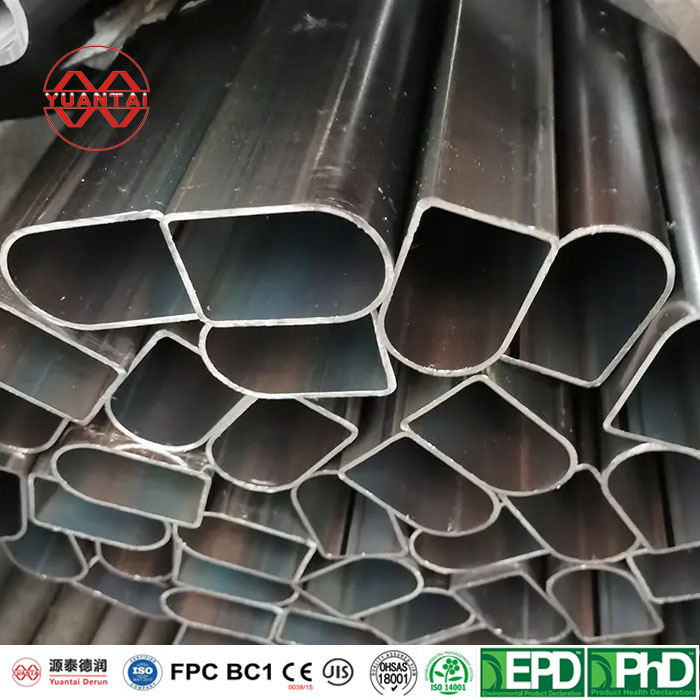

Six Angle Steel Tube,Hexagon Steel Pipe Outer Six Inner Circular Special-Shaped Steel Pipe

Hexagonal steel pipe is also called special-shaped steel pipe, including octagonal pipe, rhombic pipe, elliptical pipe and other shapes. It is an economic section steel pipe, inclu […]

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

Greenhouse Shed Circlip Dipped Plastic Circlip Manufacturer Wholesale Cartridge Compression Spring Greenhouse Accessories Slot Circlip

Greenhouse shed circlip dipped plastic circlip manufacturer wholesale cartridge compression spring greenhouse accessories slot circlip

Supply Of Zigzag Steel Clips New Type Of Zigzag Steel Framework Connecting Clips

Product name: Jizi steel skeleton accessories Product alias: zigzag steel card, zigzag steel bending connection Product description: The framework of the shed is made of zigzag ste […]

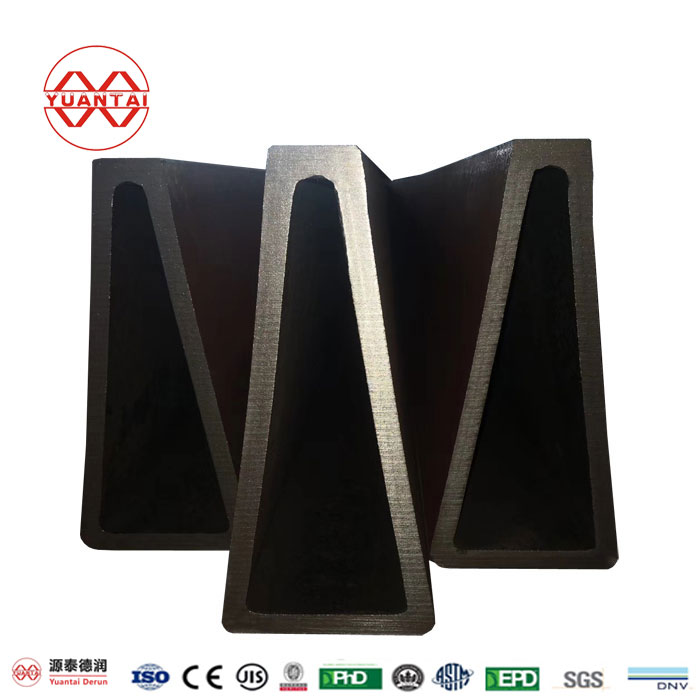

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]