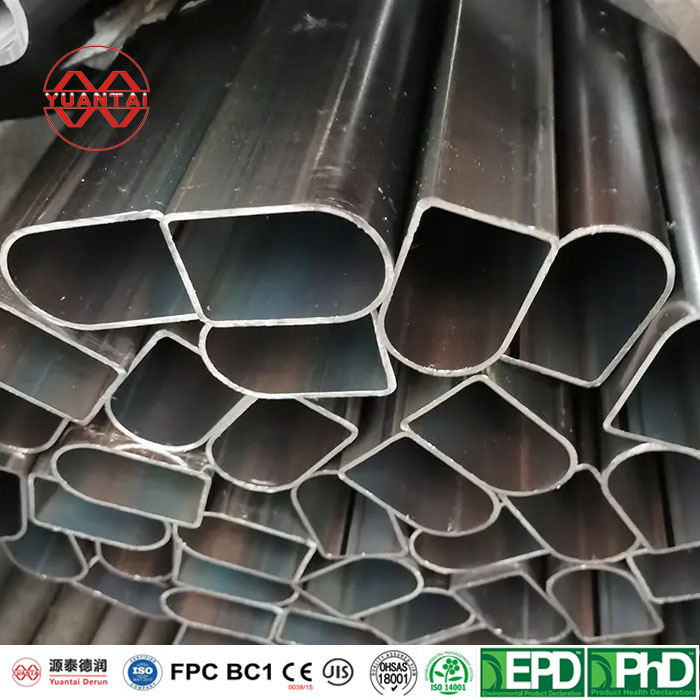

Versatility, durability, and cost-effectiveness make steel tubing ideal for a range of purposes. Steel tubing manufacturer produces the material in both round and rectangular shapes, so it can suit industrial uses to aesthetic designs. And, as a bonus, you can choose between mild steel or stainless steel for the construction of the tubing.

Steel tubing can be seen in a variety of places due to its incredible strength and versatility. From types of industrial applications to decorative designs, steel tubing is profusely used in the manufacturing, construction, and engineering fields. Its cost-effectiveness, durability, and distinct shapes—round, rectangular, and square—attract numerous projects both grand and minor in scope. As a top choice for many ambitious undertakings, steel tubing continually demonstrates its strength and proficiency.

Selecting the right steel tubing manufacturer requires careful consideration – experience and expertise in the industry are essential to ensure optimal quality. Depending on the intended application, many steel tubing manufacturers specialize exclusively in producing tubes for specific purposes, like medical instruments, automotive components, or structural building. It is important to select a manufacturer who has produced the type of tubing you require, as their knowledge and familiarity with the process will grant you a high-quality end result. On top of this, Pay attention to the quality of the steel used by the manufacturer; this will play a crucial role in determining the strength and longevity of your final product.

When requesting steel tubing from a vendor, precision is paramount to guarantee the right dimensions and shape are delivered. Furthermore, it’s crucial to ponder what type of covering should be applied which will define its corrosion and chemical resistance, as well as other qualities. In certain circumstances, further treatments like heat therapy or galvanizing may be needed to bolster protection from the environment.

Making sure there are no misunderstandings is essential when collaborating with a steel tubing manufacturer. Begin by establishing an outline of the timeline for the project and ironing out the payment plan as well as the delivery options. Also, don’t forget to ask about what protocols they implement to guarantee that what you’ll be getting meets your quality assurance standards.

When in search of a steel tubing manufacturer, you must pay close attention to the market knowledge and proficiency they possess related to the industry, and properly evaluate the coating material and grade quality of the steel before making your selection. Clear communication between the supplier and customer is vital to the timely completion of the project within budgetary boundaries. Taking the right steps to investigate the credentials of potential manufacturers can guarantee that you receive high-quality tubing complemented by ideal conditions for your project.

Steel Tubes: Unsung Heroes of Industrial Creation

Steel tubes are at the foundation of manufacturing production. From automotive to construction to plumbing, their versatile forms and sizes – ranging from round to rectangular to square – equip the industry to tackle various tasks. Not to mention, the strength of steel makes it perfect for fabrics like furniture and appliances. Ultimately, steel tubes are essential components in countless metal products.

Steel tubes are widely used for a variety of purposes and in a multitude of industries. In the automotive field, they are invaluable, employed in exhaust systems, fuel lines, and the beefing up of chassis. Moreover, construction projects such as the building of structures, bridges, and so forth require steel tubes. Most familiarly, many plumbing projects necessitate the use of steel tubing for things like pipes, valves, and fittings.

Starting out as a raw piece of steel, the manufacturing process for steel tubes sees the material transformed into durable and resilient configurations. It is sliced to size before being heat-treated to increase its strength. This is followed by the shaping of the steel tubes via either a press or a rolling machine, depending on the design required. Rounding off the process are inspections, gauging its strength, weldability and other features.

When on the hunt for a dependable steel tubes manufacturer, it is paramount to evaluate several important factors. Chief among these is the manufacturer’s experience and overall reputation – thus making sure that they have a solid history in manufacturing superior steel tubes. Moreover, the supplier ought to have the appropriate machinery and technology to give shape and form to the desired tube dimensions.

When assessing how much you need to pay for steel tubes, it is prudent to take into account the cost. Different manufacturers normally have varying price plans depending on the specifications of the tubing, so it is important to look around and inspect where you can get the best value for your money.

Before committing to a purchase, it is vital to comprehend the delivery time and return policy of steel tubes. Additionally, it is essential to guarantee that the delivered tubes agree with your specifications. Ask the producer about these details before ordering to make sure you get exactly what you need.

When seeking out a steel tube manufacturer, you must ensure that they are both dependable and well-reputed. You should also look into the pricing and delivery periods to make sure you get the most fitting deal. Moreover, it is wise to check the manufacturer’s return policy in case you are not pleased with the outcome.

Steel tubes are an essential element of many production processes, from cars to buildings to piping. As you search for a dependable steel tubes manufacturer, reflect on their years of experience, the feedback of customers who have already used their services, their cost structure, how quickly they can provide your order, and what their returns policy includes. All of these variables will help ensure that your steel tube needs are met with efficiency and dependability.

Post time: 2023-07-08

Related Product

8-Shaped Steel Pipe

8-shaped steel pipe Product Information Brand: YuantaiDerun Place of Origin: Tianjin, China Alloy Or Not: Non-Alloy Special Pipe: Thick Wall Pipe Standard: ASTMA500/A501/A53,BS1387 […]

Supply Of Zigzag Steel Clips New Type Of Zigzag Steel Framework Connecting Clips

Product name: Jizi steel skeleton accessories Product alias: zigzag steel card, zigzag steel bending connection Product description: The framework of the shed is made of zigzag ste […]

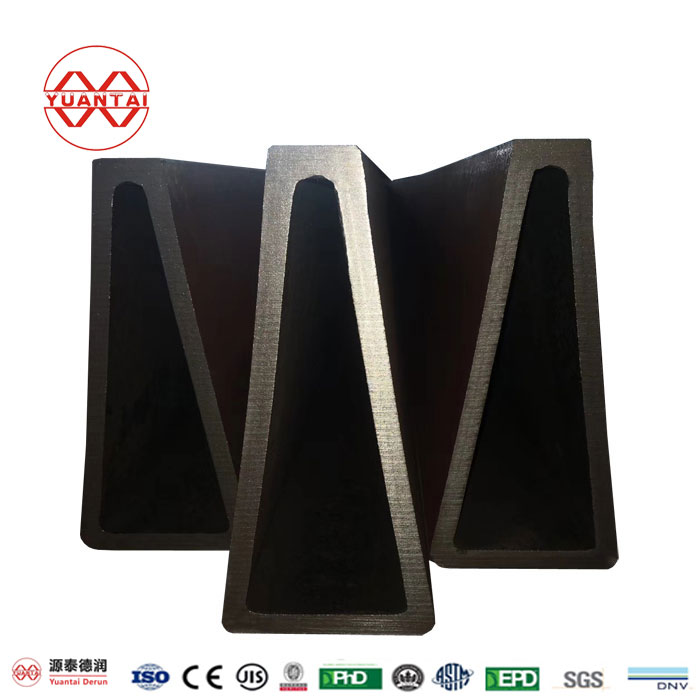

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

Six Angle Steel Tube,Hexagon Steel Pipe Outer Six Inner Circular Special-Shaped Steel Pipe

Hexagonal steel pipe is also called special-shaped steel pipe, including octagonal pipe, rhombic pipe, elliptical pipe and other shapes. It is an economic section steel pipe, inclu […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]

Special Shaped Steel Pipe Factory

Special shaped steel pipe factory

Greenhouse accessories Film roller, super strong side film roller Top windproof film roller

The shell is made of cast aluminum, which is cast by precision die-casting one-time molding process. Its raw materials and casting quality are in sync with the domestic top tier br […]