Getting the sizing right when it comes to steel tubes can have a major impact on the quality of the finished product. It’s no wonder that they’re so widely used in everything from structural support and furniture design – the precise size of these tubular metal pieces can really make a difference. So, it’s imperative that any person working with steel tubes have an understanding of all the sizes and shapes that are out there, as well as how to make sure they’re correctly portioned off for each application.

Steel tubes come in an array of sizes and shapes, from round to rectangular, square to oval. To calculate the optimal size for the job, the outer diameter (OD), inner diameter (ID), and wall thickness (WT) must be considered. The OD marks the overall circumference of the tube, the ID illustrates the diameter of the tube’s inner bore, and the WT shows the thickness of its walls. Knowing these measurements is integral to selecting a suitable product.

It is essential to take into account the purpose of use and the alloy of your steel tubes before deciding upon their size. There is an extensive array of steel tube alloys and grades available, and only the most appropriate material should be selected for your needs. Additionally, heavier metals, including carbon steel, will require bigger tubes than lighter elements like aluminum and stainless steel.

After selecting the type of material and assessing the application’s specific needs, it is necessary to take precise readings of the outer diameter (OD), inner diameter (ID), and wall thickness (WT) of the tube. This can be done with a variety of accessible tools, such as calipers, rulers, and micrometers. No matter what instrument is used, it is imperative to obtain accurate measurements for all three dimensions in order to guarantee that the tube is the perfect size for the job at hand.

To achieve the size desired for a steel tube, there are multiple approaches that can be taken. One popular option is making use of a tube cutter, which functions by employing a sharp blade to cut the material. Adjusting the blade to the proper size allows for a simple and straightforward trimming of the steel tube. Alternatively, for maximum precision in the trimming, a saw or drill press can be used, resulting in a precise cut.

It is vital to take safety precautions when measuring and manipulating steel tubes. From gloves, to goggles, to a face mask, it is important to have safety gear in order to mitigate any harm incurred while cutting or drilling the tube. Furthermore, one must guarantee that the equipment used are in optimal condition; thus, one must choose the appropriate blade or drill bit to prevent any harm that could befall the steel tube.

A precise understanding of steel tube sizing is critical for successful production: the measurements of Outer Diameter, Inner Diameter, and Wall Thickness are all essential to ascertain. Various tools and strategies can be employed to cut and drill the tubes, so that they are suitable for their purpose – and with the right diligence, those steel tubes will meet the standard required.

Deciding on steel tubing dimensions plays a critical role in any metalworking task. The size and shape you select can greatly affect the outcome of what you are creating, from robustness and stability to general performance. A few elements must be taken into account when selecting the correct steel tube sizing for a job.

With an array of steel tube sizes ranging from a tiny 1/8 inch to a hefty 5 inch, you’ll need to keep in mind the purpose of your project when selecting the ideal diameter. When assembling something that requires strength and resiliency, it would be prudent to opt for a wider tube. Conversely, if the construction is intended for malleability and portability, then you should likely look towards a narrow diameter tube.

When selecting a tube, the wall thickness should not be overlooked. This metric, expressed as inches, establishes how thick the walls of the tube are, with thicker walls translating into enhanced durability and strength. But it’s worth heeding caution; having too thick of a wall can make the tube overbearingly hefty for certain purposes.

When choosing your steel tube, the type of alloy present in the metal should be taken into account. Steel is made up of an array of unique blends, each one offering different results depending on their application. For instance, certain alloys are more airtight than others while some are much more adept for welding. By selecting the appropriate alloy for your task, you can guarantee that your tubing is perfectly fit for purpose.

The ultimate finishing touch for your tubing is deciding its type of treatment. A few popular choices are galvanized steel, coated steel, and stainless steel. Of the three, galvanized steel is the most economical choice – perfect for outdoor use. The coating on coated steel helps extend its lifespan thanks to improved defense against corrosion. Most pricey but also extremely corrosion-proof is stainless steel, which is commonly employed in medical and food-related industries.

To construct a project that meets expectations, selecting the ideal steel tube size and configurations is critical. This varies based on various elements, including size, wall thickness, alloy, and surface finish. With the perfect blend of these salient features, your work can be accomplished effectively with the most suitable materials.

Post time: 2023-08-26

Related Product

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

OVAL TUBE BASE GREENHOUSE ACCESSORIES OVAL TUBE GREENHOUSE CONNECTOR CLAMP

The base of oval tube in greenhouse is no stranger to those who have been exposed to greenhouse equipment. In the installation project of greenhouse equipment, the products of oval […]

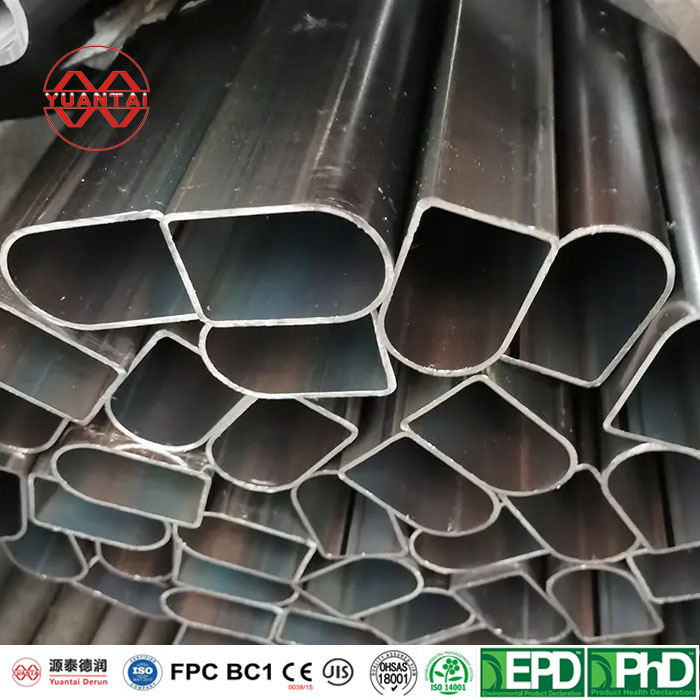

Special Shaped Steel Pipe Factory

Special shaped steel pipe factory

Supply Of Zigzag Steel Clips New Type Of Zigzag Steel Framework Connecting Clips

Product name: Jizi steel skeleton accessories Product alias: zigzag steel card, zigzag steel bending connection Product description: The framework of the shed is made of zigzag ste […]

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

Greenhouse Shed Circlip Dipped Plastic Circlip Manufacturer Wholesale Cartridge Compression Spring Greenhouse Accessories Slot Circlip

Greenhouse shed circlip dipped plastic circlip manufacturer wholesale cartridge compression spring greenhouse accessories slot circlip

Octagonal Steel Pipe

Tianjin Yuantai Derun Group has 18 wholly-owned subsidiaries, of which Tianjin Yuantai Technology Development Co., Ltd. was founded in 2014 to produce super large diameter, super t […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]