Steel tube bending is a process enabled by a range of machines, yet the most widely-employed is the rotary draw bender. This forms bends within the steel tube via mounting a die onto a mandrel. The latter is inserted into the steel and when rotated, the tube is drawn by way of the die. Whether it be a hydraulic or pneumatic machine, this action renders industry-standard curves.

Before embarking on steel tube bending calculations, it is essential to consider the wall thickness, diameter, and length of the tube. These three dimensions will determine the minimum radius that can be achieved, the force needed for the bending process, and the amount of time it will take to complete it.

When it comes to bending steel tubing, wall thickness plays a pivotal role in the calculations involved. This is due to the fact that a specific mathematical equation is used to determine the minimum bend radius, wherein R represents the minimum radius, WT stands for the tube wall thickness, and the constant 2 is inputted for completion. For illustration, if the steel tube wall thickness happens to be 0.5 inches, then the resulting minimum radius of the bend will be 0.5 inches.

The size of the steel tube impacts the magnitude of force needed for it to be bent. The larger the diameter, the greater the power that must be applied in order to complete the bending process. This relationship can be calculated through an equation: F=PD/4t., with F representing the force necessary for bending, P presenting the pressure used on the tube, D identifying the tube’s diameter, and t denoting its thickness. To illustrate this concept, a two-inch-wide tube with a 0.5-inch wall thickness would require 4,000 pounds of power to bend.

Bending a steel tube takes a certain amount of time, and its length can have a dramatic effect on this. For instance, by using the equation T=L/RT, which takes into account the tube length (L), bends’ radius (R) and its thickness (T), we can calculate that if a steel tube of 10 feet is to be bent to a radius of 1 foot, 10 minutes will be needed for the process.

Accurate calculations related to steel tube bending are essential for determining the needed amount of force for its bending, the minimum curvature achievable, as well as the total time consumed in executing the procedure.

Post time: 2023-07-02

Related Product

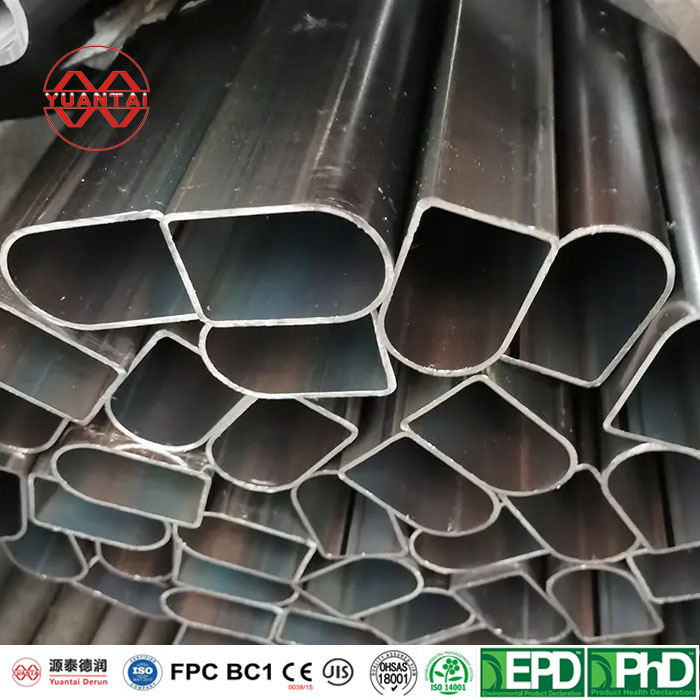

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

Greenhouse accessories Film roller, super strong side film roller Top windproof film roller

The shell is made of cast aluminum, which is cast by precision die-casting one-time molding process. Its raw materials and casting quality are in sync with the domestic top tier br […]

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

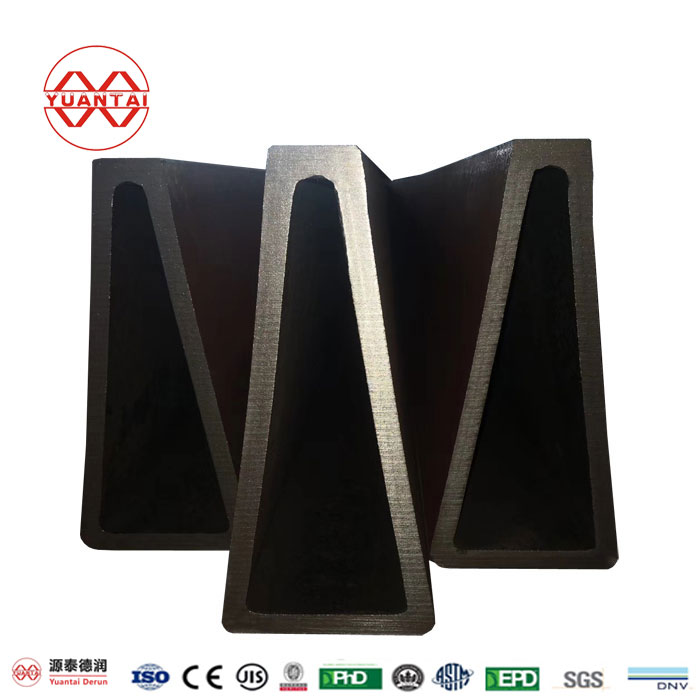

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

Supply Of Zigzag Steel Clips New Type Of Zigzag Steel Framework Connecting Clips

Product name: Jizi steel skeleton accessories Product alias: zigzag steel card, zigzag steel bending connection Product description: The framework of the shed is made of zigzag ste […]

Six Angle Steel Tube,Hexagon Steel Pipe Outer Six Inner Circular Special-Shaped Steel Pipe

Hexagonal steel pipe is also called special-shaped steel pipe, including octagonal pipe, rhombic pipe, elliptical pipe and other shapes. It is an economic section steel pipe, inclu […]

Steel Wire Ground Anchor, Fixed Pressure Film Rope For Greenhouse, Ground Anchor, Embedded Part Of Ground Pile For Greenhouse, Steel Wire Ground Anchor

Steel wire ground anchor, fixed pressure film rope for greenhouse, ground anchor, embedded part of ground pile for greenhouse, steel wire ground anchor Steel wire anchor is directl […]