ASME, or the American Society of Mechanical Engineers, is an organization that sets stringent criteria for the planning, formation, and distribution of pipes and other vessel components. This body is renowned for its precision and meticulousness, with pipe ovality tolerance as a crucial feature of their regulations. Ovality stands for a pipe’s divergence from its perfect circular appearance. Consequently, ovality tolerance is the maximum divergence that these vessels can have from their ideally round profile.

When inspecting a pipe for accuracy, the ASME standards are especially demanding in respect of ovality specifications. This roundness is referred to as the “tolerance” and denotes the acceptable degree of variation around the ideal shape.The tolerance requirements vary based on the pipe size and pressure it will be subject to; usually, the larger sizing comes with more stringent requirements.

According to ASME standards, the roundness of a pipe is quantified as ‘tolerance of ovality’. This metric expresses the maximum difference permitted between the pipe’s true shape and its targeted roundness/cylindrical pattern. To illustrate: for an 8 inch pipe, with a 0.5% tolerance of ovality, the furthest allowable deviation from a perfect circle would amount to 0.04 inches.

According to the ASME standard, not only must a pipe meet a specified degree of ovality, but it must also adhere to a “tolerance of straightness”. This is calculated in inches per foot, with anything over being an unacceptable variation from what is deemed straight. For example, with a 0.02 inches per foot tolerance of straightness, anything above that figure will not pass muster.

The ASME regulation outlines the “tolerance of the line-up” between pipes. This is the total variation permitted from the perfect joint of two pipes connecting. This tolerance is made known in degrees; for example, if the allowable variability is 1 degree, then the maximum divergence from perfect alignment must not exceed 1 degree.

With regard to the ASME standard, the “tolerance of cut” for piping is outlined. This expression determines the maximum allowable distance from standard cutting of any pipe. It is measured in inches for each foot and is illustrated with a sample: if the tolerance of cut is 0.02 inches per foot, only 0.02 inches can deviate from the exact cut of the pipe.

In a nutshell, the ASME standard outlines rigorous guidelines when it comes to ovality variation in pipes. This variation is quantified in relation to the nominal size of the pipe, while the straightness must adhere to an inches per foot limit and the alignment degree allowance is clearly laid out. Cutting requirements are strictly stipulated in inches per foot to ensure that pipes adhere to a high quality of engineering and reliable safety measures when they are utilized as intended.

Fluctuations in Pipe Dimensions Critical for ASME Infrastructure Needs

ASME pipe shapes and sizes are subject to critical requirements due to ovality tolerance standards. In order to ensure piping systems remain safe to use for facility purposes, it is essential to consider the exacted standards of pipe ovality. Effectively adhering to these strict ASME dimensions can ensure that mechanical systems are able to work without disruption from inaccuracies present in the piping network. Thus, it becomes a priority for businesses and industries worldwide operating through an ASME infrastructure to remain highly attentive when considering changes in pipe dimensions.

The functional reliability and safety of piping systems depend on meeting its ovality tolerance threshold. That is why the American Society of Mechanical Engineers (ASME) has created a standard for such tolerance, which is widely embraced within the industry. This article provides an overview of the concept of pipe ovality tolerance, why it is an integral element to consider in design and installation, as well as how the ASME standard guarantees the efficient performance of piping systems.

The research of a pipe’s profile extends beyond its length, and accuracy in roundness over its circumference is paramount. This quality is referred to as ovality, and is determined by the contrast between the widest and narrowest points on the pipe perimeter. A pipe in the range of 0.5% ovality or below is typically given the seal of approval for appropriate use.

Pipe ovality is incredibly relevant, as it plays a key role in the transportation of gases and fluids. If the ovality is excessively high, this can increase turbulence and create a cavitation effect, leading to reduced efficiency and potential damage to the infrastructure itself. Additionally, an oval-shaped pipe is more prone to fractures and leaks, thus making its structural integrity more vulnerable than expected.

The ASME code faculty states that if a pipe’s nominal diameter is 2 inches and the pressure rating is 300 PSI, its maximum ovality tolerance must not exceed 0.75%. In other words, the variance between the biggest and smallest diameters of the pipe must be under 0.75% of its nominal width.

The ASME standard is crucial for impeccable piping system implementation and correct and risk-free functionality. An excessive ovality tolerance can cause turbulence and cavitation, which will significantly hinder the flow and have damaging effects on the pipe. Furthermore, there is an escalated possibility of cracking or leakage once an oval pipe has been installed.

Maintaining the appropriate ovalness of pipes is critical for a wide range of commercial ventures, from power plants to water treatment systems, and from chemical factories to oil and gas production sites. Meeting the ASME standard in this regard is fundamental for guaranteeing the safe and efficient functioning of the entire piping arrangement.

In the end, the shape of pipes is a key factor to keep in mind throughout the setup of any piping system. The ASME guidelines regarding pipe ovality offer a necessary assurance that the components are set up properly so they run efficiently and risk-free. All pipe set-ups must abide by the respective ASME limits for a secure and dependable operation.

Post time: 2023-08-18

Related Product

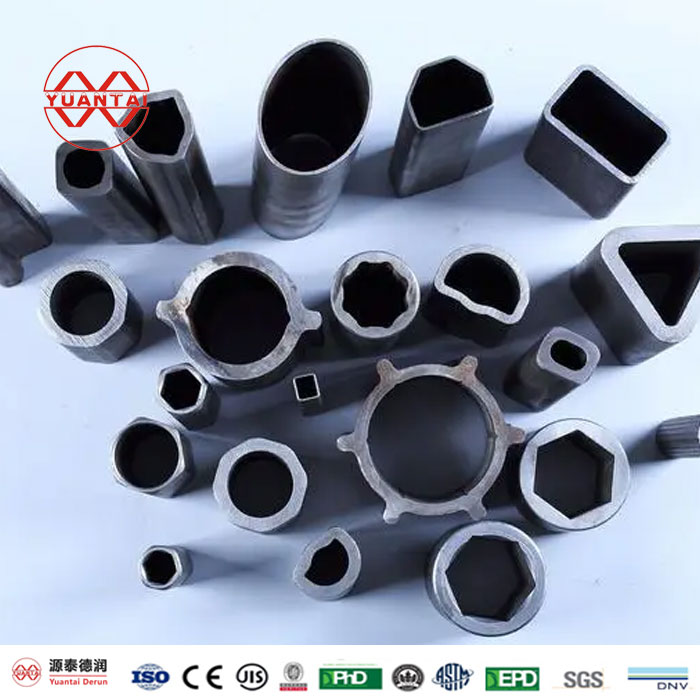

Six Angle Steel Tube,Hexagon Steel Pipe Outer Six Inner Circular Special-Shaped Steel Pipe

Hexagonal steel pipe is also called special-shaped steel pipe, including octagonal pipe, rhombic pipe, elliptical pipe and other shapes. It is an economic section steel pipe, inclu […]

8-Shaped Steel Pipe

8-shaped steel pipe Product Information Brand: YuantaiDerun Place of Origin: Tianjin, China Alloy Or Not: Non-Alloy Special Pipe: Thick Wall Pipe Standard: ASTMA500/A501/A53,BS1387 […]

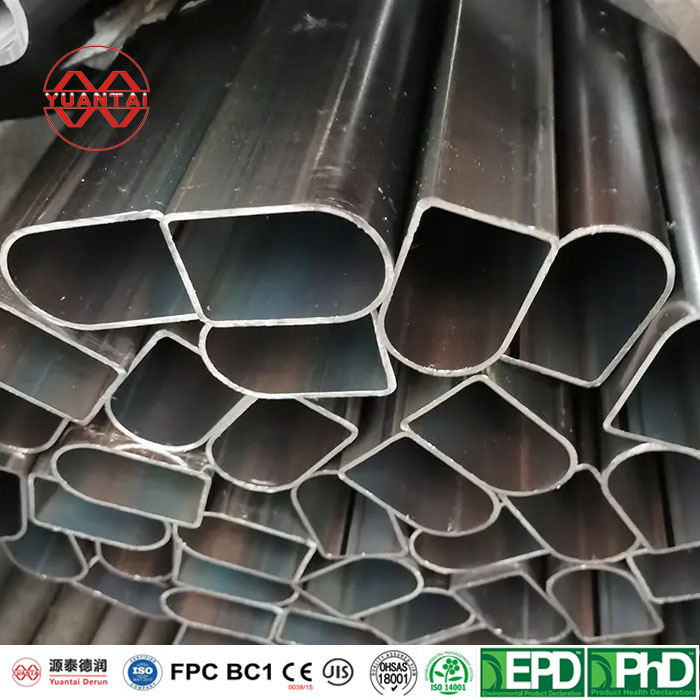

Special Shaped Steel Pipe Factory

Special shaped steel pipe factory

Greenhouse Shed Circlip Dipped Plastic Circlip Manufacturer Wholesale Cartridge Compression Spring Greenhouse Accessories Slot Circlip

Greenhouse shed circlip dipped plastic circlip manufacturer wholesale cartridge compression spring greenhouse accessories slot circlip

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]