Moment of inertia is a pivotal concept in the mechanics and engineering world, especially where steel tubes are concerned. Its importance lies in helping to gauge both the rigidity and potency of metal tubes as well as estimating the required magnitude of pressure to distort or bend them. This article will discuss the nature & essence of moment of inertia, its calculations relating to steel tubes, and its practical applications.

The resistance of a body to rotation around a certain axis is known as its moment of inertia. By multiplying the mass of the body and the square of its distance to the rotation axis, we can measure this resistance. From here, we can compute the rotational inertia, or the opposition to being turned in an angular direction, and also calculate angular momentum, which is the product of mass and angular velocity.

In order to determine the moment of inertia for a steel tube, its cross sectional area and length must be factored in. If the tube is round, its polar moment of inertia can be calculated using the equation I = r^4/4, where r is the radius of the tube. For a square steel tube, a different calculation is used to determine its moment of inertia of the area; this factor can be calculated using I = bh^3/12, with b being the width and h being the height of the tube.

To comprehend the robustness and power of steel tubes, the moment of inertia is vital. It measures how much force must be applied for a tube to bend or morph. Additionally, torque and energy required for acceleration is measured through this parameter. Thus, it gives us a better insight as to the quantity of strength needed to rotate or move them.

From determining energy dissipation to pinpointing fatigue life, the moment of inertia plays a crucial role in processing steel tube deformations. As a matter of fact, the higher the moment of inertia, the less energy is needed to be expended and thus the extended life span of the steel tube is achievable.

In order to ascertain the necessary energy expenditure when putting a steel tube through torsional loading – when a force is exerted on the tube to spin it and stretch it – the moment of inertia needs to be considered. Moment of inertia is highly influential in determining how much effort must be expended for this activity.

Ultimately, the moment of inertia is an essential factor in crafting steel tubes. Designers leverage it to find the perfect shape and size for each tube, taking into consideration the force and torque that it will be exposed to. This calculation technique helps ensure that the tube will be sufficiently stiff and resilient to withstand any applicable forces and torques.

When it comes down to it, moment of inertia is essential when it comes to grasping the robustness and solidity of steel tubes. It is used to discover the amount of pressure and turning force that need to be used for bending and warping them, as well as the amount of vigor required for quickening and slowing down the tubes. Also, it is part of the plan for designing the steel tubes so that they are as enduring and rigid as humanly possible.

When it comes to engineering, moment of inertia – also known as the second moment of area – is an invaluable concept used to decide how an object responds to rotational force. The measure determines the mass distribution from an organism’s rotation axis and is especially integral to the construction of structures such as bridges, towers, and high-rises that need to withstand extreme environmental conditions. Steel tubes are frequently included in the design of these edifices, so ascertaining its moment of inertia is an integral step in engineering design.

When considering moment of inertia, an illustrative example comes to mind. Suppose we have two steel tubes with identical weight, each of 10 kilograms. However, the first is a straight line tube while the second is curved into a loop. It stands to reason that the second tube will be sturdier when it comes to rotational forces. That is because its mass is distributed along a longer radius giving it superior resistance to rotation. Although this example involves steel tubes, the concept carries over to calculate the moment of inertia of other materials.

In order to ascertain the moment of inertia of a steel tube, it is necessary to find out its mass by determining the density of the steel and the cross-sectional area of the tube. Generally, the density of steel varies between 7.8 and 8.0 grams per cubic centimeter. Subsequently, this Mass can be used to work out the moment of inertia.

To get the moment of inertia for a steel tube, one needs to start by ascertaining its radius of gyration – the distance between the axis of rotation and its centre of gravity. In the case of a steel tube with a circular cross-section, this is simply equal to its radius. From there, one can use the following equation to find the tube’s moment of inertia, which is determined by multiplying the mass by the square of its radius of gyration.

The Relationship of Inertia and Moment of Inertia in the Square

The Moment of Inertia (I), Mass of the Tube (m), and Radius of Gyration (r) are all integral components to consider when undertaking a project which requires efficient inertial motion.

By multiplying the tube’s moment of inertia by its rotational velocity, we can discern the steel tube’s resilience to any rotary forces. The speed of rotation, expressed as revolutions per minute (RPM), gives us the rate at which the tube is spinning. Further calculations from these two values allow us to find the level of resistance from the tube.

A steel tube of mass 10 kilograms and gyroscope radius 0.5 meters can provide an interesting example. Computing this tube’s moment of inertia via the corresponding equation yields 1.25 kg•m^2. Assuming it is spinning at a 30 RPM angular velocity, the tube’s angula resistance to rotary forces can be calculated as 37.5 kg•m^2•s^-1 (kilogram•meter2•seconds-1) by multiplying its moment of inertia by the angular velocity.

When formulating Bridges and other large constructions, engineers must take into account the moment of inertia of a steel tube. This figure permits them to gauge its resistance to rotational forces – an essential component for keeping a creation stable. In essence, knowing how to calculate the moment of inertia for steel tubes can help engineers create strong and secure edifices.

Post time: 2023-08-08

Related Product

Greenhouse Shed Circlip Dipped Plastic Circlip Manufacturer Wholesale Cartridge Compression Spring Greenhouse Accessories Slot Circlip

Greenhouse shed circlip dipped plastic circlip manufacturer wholesale cartridge compression spring greenhouse accessories slot circlip

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]

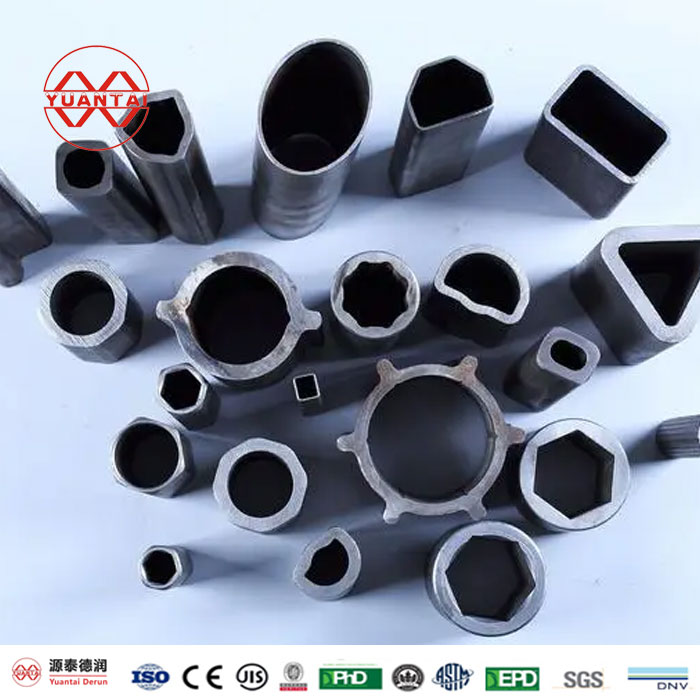

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

Special Shaped Steel Pipe Factory

Special shaped steel pipe factory

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

8-Shaped Steel Pipe

8-shaped steel pipe Product Information Brand: YuantaiDerun Place of Origin: Tianjin, China Alloy Or Not: Non-Alloy Special Pipe: Thick Wall Pipe Standard: ASTMA500/A501/A53,BS1387 […]

Octagonal Steel Pipe

Tianjin Yuantai Derun Group has 18 wholly-owned subsidiaries, of which Tianjin Yuantai Technology Development Co., Ltd. was founded in 2014 to produce super large diameter, super t […]

Six Angle Steel Tube,Hexagon Steel Pipe Outer Six Inner Circular Special-Shaped Steel Pipe

Hexagonal steel pipe is also called special-shaped steel pipe, including octagonal pipe, rhombic pipe, elliptical pipe and other shapes. It is an economic section steel pipe, inclu […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]