Mig welding has been employed for years to connect two chunks of steel. This method is uncomplicated, and its employing range is wide, granting you the freedom to coalesce all varieties of steel, comprising stainless steel.

To begin mig welding tube steel, the commencement of the process requires the area to be cleared of dirt and other potential obstructions, with cleanup of the space being paramount. Following this important step, your welder must then be set up for welding.

To ensure the two pieces of steel remain securely fastened, a tack weld is the way to go. This process involves welding them together in an area of limited size. This will give peace of mind that they won’t shift or move as you complete the weld. Before you begin this, be sure your welding equipment is all set up and ready to go.

To have your two pieces of steel successfully joined, first use a tack welder to bring them together and then use a mig welder to finish the job. The magic ingredient here is the filler rod, which is essential for welding the two parts into one cohesive unit.

For an effective bond, a layer of gas must be utilized to serve as a shield from the ambient air. Additionally, this gas will help to lower the temperature of the weld so it can stand the test of time.

After connecting the steel pieces with the MIG weld, the subsequent step is to provide it with a period of cooling. This can be achieved by letting the weld stand or deploying a coolant for a span of several minutes.

When the newly formed weld has had some time to cool off, the tack welds can then be carefully removed. You can turn to either a chisel or a trusty grinder for this step of the welding process.

In order to perfect the weld, you should take the time to grind it down until its surface is seamless and flush with the steel’s surface. Doing this ensures that the weld looks and feels smooth.

Now you have the opportunity to join the two slabs of steel seamlessly using a MIG welder. Be certain that all welds are created in the same vector for optimal adherence.

Working with steel, it’s essential to be mindful of how close you weld to the edge; getting too close could fracture the material.

Once you join the two pieces of steel together via welding, you can then take away the fuel and the filler rod. Afterwards, it is essential to examine the weld to ascertain that it is solid.

With a few brushstrokes of paint, you can provide a layer of protection to the weld against exposure to the environment. Alternatively, applying a sealant over the weld will also preserve it from the outside world.

Now, you have access to a mig welder which offers a range of welding capabilities – from stainless steel and aluminum to any other type of steel. With this innovative tool, you’ll be able to join together an exhaustive range of materials with ease.

Post time: 2023-06-28

Related Product

Steel Wire Ground Anchor, Fixed Pressure Film Rope For Greenhouse, Ground Anchor, Embedded Part Of Ground Pile For Greenhouse, Steel Wire Ground Anchor

Steel wire ground anchor, fixed pressure film rope for greenhouse, ground anchor, embedded part of ground pile for greenhouse, steel wire ground anchor Steel wire anchor is directl […]

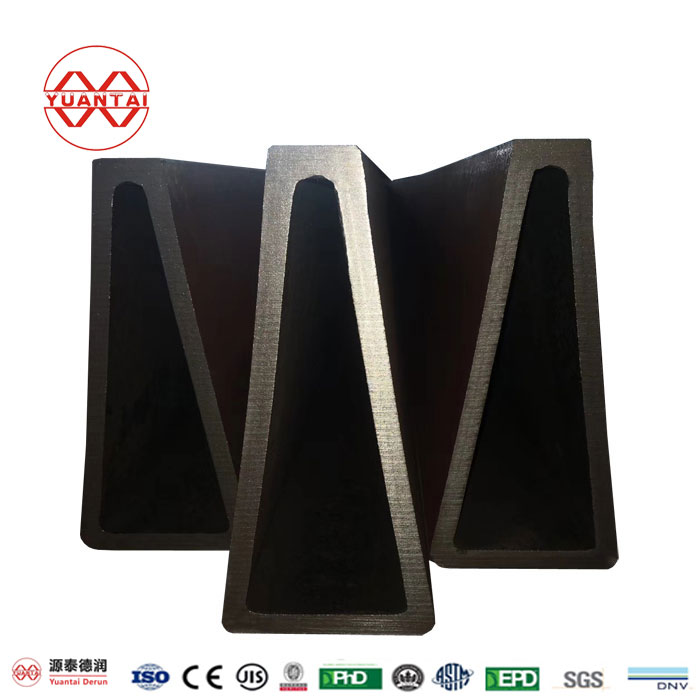

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

Special Shaped Steel Pipe Factory

Special shaped steel pipe factory

8-Shaped Steel Pipe

8-shaped steel pipe Product Information Brand: YuantaiDerun Place of Origin: Tianjin, China Alloy Or Not: Non-Alloy Special Pipe: Thick Wall Pipe Standard: ASTMA500/A501/A53,BS1387 […]

Octagonal Steel Pipe

Tianjin Yuantai Derun Group has 18 wholly-owned subsidiaries, of which Tianjin Yuantai Technology Development Co., Ltd. was founded in 2014 to produce super large diameter, super t […]

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]