Steel tubes represent an incredibly versatile solution for engineering and construction needs, seen everywhere from structural supports and piping to spectacular large-scale architectural designs. The load capacity of these metals, however, is essential to consider when assessing their usefulness – their efficiency hinges upon it. In effect, understanding the properties that comprise the load capacity of steel tubes must be taken into account for successful implementation.

The potency of steel tubes is rooted in a blend of carbon and iron, these two elements working together to generate a stout and dependable end-product. The ratio of carbon to iron will influence the resilience of the material, reflecting on its ability to handle weight. Generally, the more carbon present in the mix, the sturdier and tougher the steel tube will be, providing higher load capacity for whatever it carries.

As well as the nature of the steel, other aspects can also influence the ability of steel tubes to hold weight. The wall thickness can make a difference, with thicker walls enabling more weight than thinner ones. The proportions and dimensions of the tube can likewise have an effect on how much it can handle; bigger tubes are stronger than smaller tubes.

In order to determine a given steel tube’s load capacity, its corrosion resistance is vital. Corrode can diminish the steel’s power and impact its ability to carry weight, so it is best to select a tube that is up-to-par in this area. Adding an additional protective layer of shielding will also guarantee further protection against corrosion, resulting in an even enhanced load capacity.

Ultimately, the atmosphere in which steel tubes are operated may also impact the load-bearing ability. Should the tubes be exposed to extreme heat or hazardous chemicals, their max capacity may lessen and should thus be dealt with attentively.

When it comes to steel tubes, the load bearing capacity is determined by composition, wall thickness, shape, size, corrosion resistance, and encircling environment. Being aware of these facets is paramount for guaranteeing the proper and secure usage of steel tubes in a broad selection of engineering and constructing endeavors.

Through precise selection of steel tubes involving composition, wall thickness, shape, size, and corrosion protection, engineers and construction experts can maximize the load capability of these steel tubes while ensuring them to be used with safety and efficiency.

Steel tubes are a key element in many industrial and structural operations, and their capacity to withstand stress is relevant when making the call on whether to deploy them for a project. In the following piece, we will explore the strength of steel tubes, the aspects that impact it, and the various methods to measure it.

Alloyed steel is the predominant material used for creating steel tubes. This metal alloy consists of iron, carbon, and other components, such as chrome, manganese, molybdenum, and nickel. By introducing these elements to the steel framework, the overall strength of the substance is improved and its ability to sustain weight increases. Carbon steel, in particular, is highly valued due to its superior load carrying capacities.

The ability of a steel tube to hold a load is determined by several factors – its material composition, thickness of the walls, diameter, and length. To boost its carrying capacity, various alloying additives, such as chromium, molybdenum and nickel, can be added to the material of the tube. In addition, the load capacity is affected by the gauge of the walls; thicker walls offer more support for the weight. The same is true for larger diameters which can also support a greater burden.

In order to determine the weight-bearing capacity of a steel tube, there are numerous options available. One of the most regularly used methods is to estimate the maximum load that can be imposed upon the tube, based on its material properties, wall thickness, diameter, and length. This can be done with an array of computer algorithms as well as with online calculators. On top of that, a laboratory test may be conducted: a known weight is placed on top of the tube and then measured to see how much deformation takes place.

The load capacity of a steel tube is immediately impacted by its environment. At high temperatures, rigidity decreases and the metal takes on a more malleable quality, decreasing the load’s capacity. On the other hand, cold climates result in increased stiffness, allowing for higher loads to be carried safely. Similarly, high humidity weakens the structure, leaving it open to damage from corrosion and reducing its load capacity.

No matter its load capacity, any steel tube must be tested for its fatigue strength – the capacity to withstand repeated loads over time. The material composition, wall thickness, diameter, and length of the tube are all contributing factors, as is the frequency and history of how it has been loaded. Its fatigue strength is determined by the numerous cycles it has gone through and the strain put upon it during those load experiments.

Ultimately, it is critical to assess the load-bearing capacity of steel tube when deciding which material to use for a specific purpose. The element, diameter, length and wall thickness all play a role in this calculation; in addition, the fatigue strength should be examined too, considering the amount of times it is loaded and how intensely. This can be ascertained through assessments conducted in a professional laboratory.

Post time: 2023-08-09

Related Product

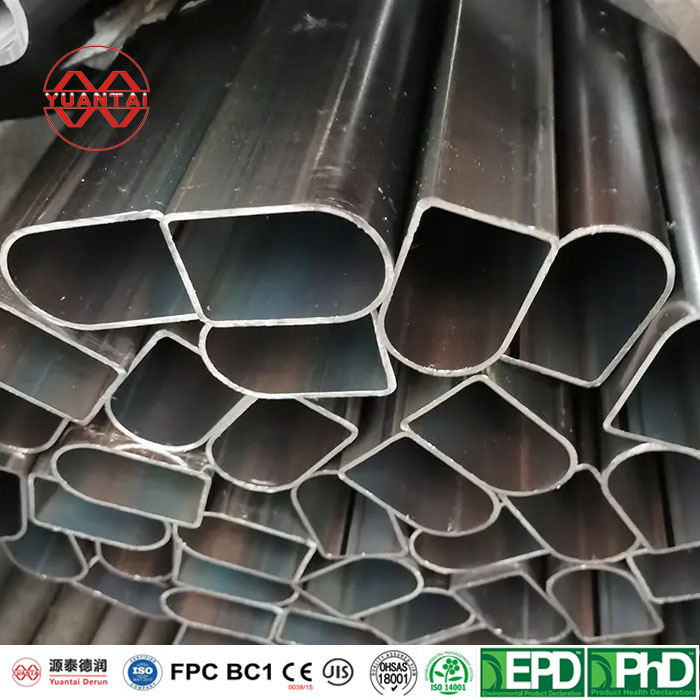

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

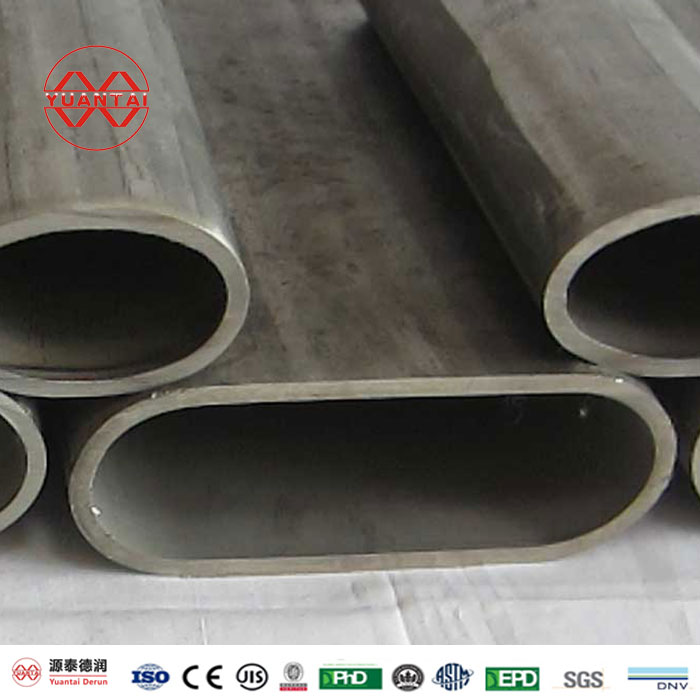

Wholesale Hot-Dip Galvanized Oval Pipe Q235B Galvanized Steel Pipe Installation Of Bendable Greenhouse Pipe

The energy-saving solar greenhouse is the most economical and practical greenhouse type among greenhouse types, because this type of greenhouse can be used for winter vegetable cul […]

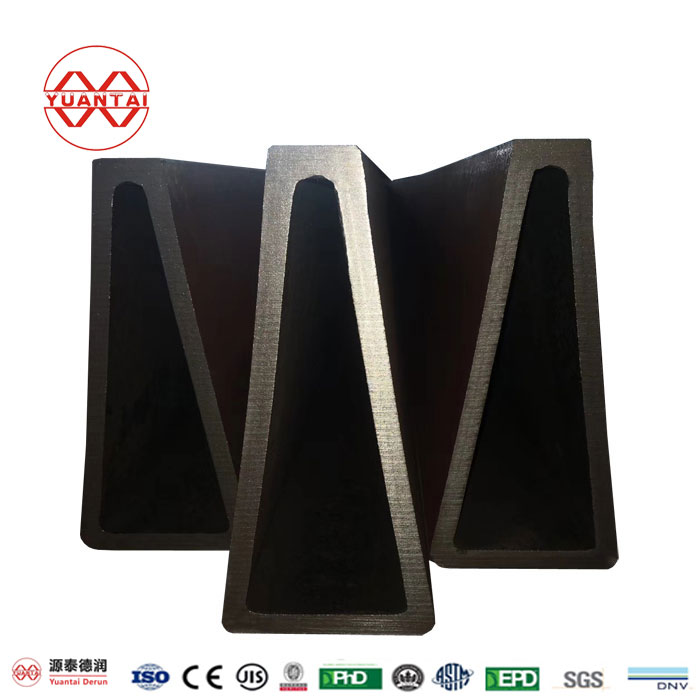

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

8-Shaped Steel Pipe

8-shaped steel pipe Product Information Brand: YuantaiDerun Place of Origin: Tianjin, China Alloy Or Not: Non-Alloy Special Pipe: Thick Wall Pipe Standard: ASTMA500/A501/A53,BS1387 […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

Special Shaped Steel Pipe Factory

Special shaped steel pipe factory

Steel Wire Ground Anchor, Fixed Pressure Film Rope For Greenhouse, Ground Anchor, Embedded Part Of Ground Pile For Greenhouse, Steel Wire Ground Anchor

Steel wire ground anchor, fixed pressure film rope for greenhouse, ground anchor, embedded part of ground pile for greenhouse, steel wire ground anchor Steel wire anchor is directl […]

OVAL TUBE BASE GREENHOUSE ACCESSORIES OVAL TUBE GREENHOUSE CONNECTOR CLAMP

The base of oval tube in greenhouse is no stranger to those who have been exposed to greenhouse equipment. In the installation project of greenhouse equipment, the products of oval […]

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]