A honed steel tube is not your typical metal tubing; it has a special surface that is finished with remarkable precision. To create this uniform-textured finish, the steel tubing undergoes a honing process which polishes away any irregularities to generate a highly accurate surface. This technique is particularly utilized when assembling hydraulic cylinders as they need perfect surfaces in order for them to work efficiently.

Enduring sharpness can be achieved when a steel tube undergoes honing. This procedure often involves the use of diamond abrasive, which is applied in a consistent flow in a specialized machine. The diamond abrasive chips away particles of the tube gradually, sculpting it to a precise, polished finish. In this way, the steel tube is gradually honed into a superior surface.

When creating a smooth finish on steel tubing, the honing process has a clear edge over grinding and sanding. It’s exactness ensures precision and thus lends itself to projects that require exactness such as hydraulic cylinders. In addition, honing avoids any heat-induced damage due to its process.

Steel tubing with a carefully polished surface is the ideal material in the construction of hydraulic cylinders, as it allows for a superior seal between the cylinder and the piston. It’s high-precision finish can improving functioning, whilst its greater durability helps to prolong the service life of the system.

For components requiring precision, honed steel tubing is the ideal option. The treated surface of the tube reduces the amount of friction between parts, resulting in improved performance and longevity for the item. Reduced wear and tear means that durability is far superior compared to untreated tubing. These qualities make it an ideal choice for uses such as bearing races, valve bodies and other components.

A sleek, sophisticated finish is the hallmark of honed steel tubing, making it a hit among those who want a stylish look. This uniform tubing can be produced in an array of colors and finishes, granting consumers the freedom to express their own unique taste. Whether you choose something classic or daringly distinctive, a honed steel tube is guaranteed to turn heads and look luxurious.

It is essential to search for the right honed steel manufacturer that is proficient in the honing process. Different manufacturing methods, materials used, and even the type of steel tubing will have an impact on the finished honed surface. Keep this in mind before making a selection to ensure that the end product meets your expectations.

Ultimately, honed steel tube is a kind of metal tubing having an accurate, machined exterior. This type of steel tubing is usually utilized in hydraulic cylinders due to its finely crafted surface. Not only is precise honing necessary for its practical use, but polishing also adds an additive aesthetic element to the tube. To get the best use and quality from this material, it’s important to consider a manufacturer who has years of honing experience.

Seamless steel tubes crafted through honing create a smooth, uniform surface on the interior ideal for operating under pressure. Such rigorous details are met for use in hydraulic and pneumatic systems where a tight seal must be held between components. Though this finessed construction is utilized universally across various industries, such honed steel tubes are heavily relied on for the creation of machinery and other piping installations like valves.

Crafting a flawless inner surface of any tube requires systematic honing. This process is done by utilizing a honing tool, which holds a honing stone in position as it is inserted into the tube. The stone then progressively applies abrasion until a uniform, polished surface is achieved. In no time, the honed steel tube is ready to be utilized for whatever the task may be.

Perfection of steel tubes can be accomplished either manually or with the use of the honing machine. With manual honing, a honing stone in the master’s hand is all that is needed to work on the material, however machine honing is when the honing machine is used with its revolving honing stone to gain an expedited level of completion.

To guarantee success when honing steel tubes, it is paramount to select the right-sized honing stone. It needs to be somewhat bigger than the inside diameter of the tube in order to finish with a smooth and even surface. Pick a size that is too small, and you risk not achieving the desired outcome. Moreover, you should select a honing stone constructed from a material that is robust and able to withstand the extreme heat created while honing.

Completing the honing process culminates in the production of a honed steel tube, designed for various uses. These tubes make excellent pipeline components for both hydraulic and pneumatic systems due to their polished surface which ensures superior sealing compatibility between components. Additionally, honed steel tubes are a common material found in the production of large-scale machinery, as well as pipes and valves.

As a critical part of many professional and domestic demands, honed steel tubes are crafted through honing–an action that provides a uniform interior surface, ideal for creating a secure connection between components. Beyond industrial and mechanical missions, these tubes are often seen as a component of machinery parts, pipes, and valves.

Post time: 2023-08-12

Related Product

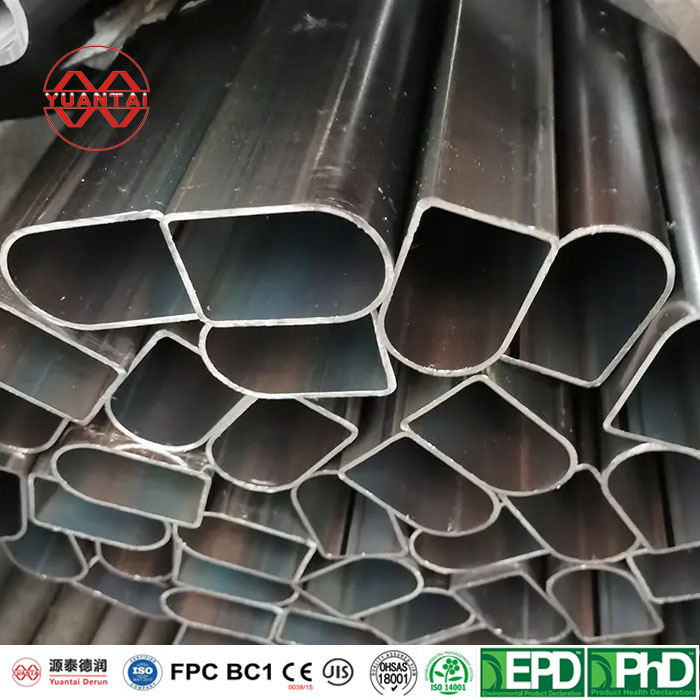

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

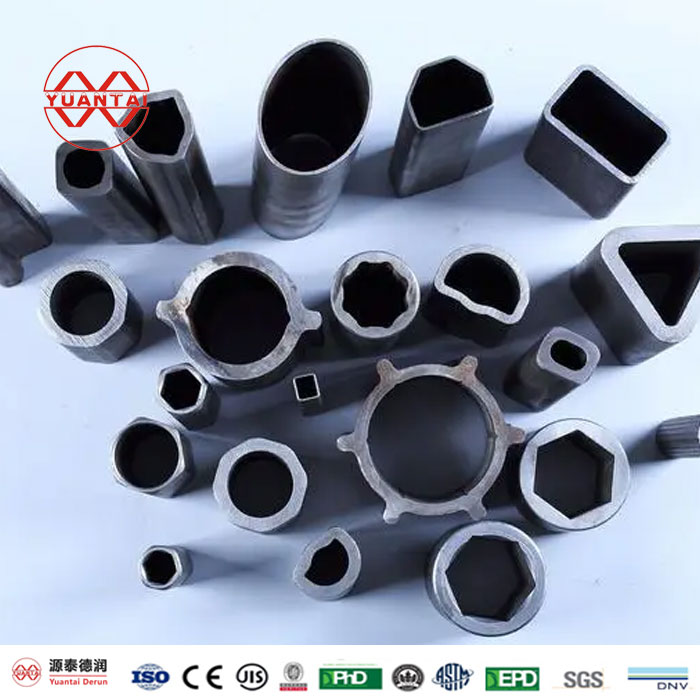

Octagonal Steel Pipe

Tianjin Yuantai Derun Group has 18 wholly-owned subsidiaries, of which Tianjin Yuantai Technology Development Co., Ltd. was founded in 2014 to produce super large diameter, super t […]

Steel Wire Ground Anchor, Fixed Pressure Film Rope For Greenhouse, Ground Anchor, Embedded Part Of Ground Pile For Greenhouse, Steel Wire Ground Anchor

Steel wire ground anchor, fixed pressure film rope for greenhouse, ground anchor, embedded part of ground pile for greenhouse, steel wire ground anchor Steel wire anchor is directl […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

Greenhouse Shed Circlip Dipped Plastic Circlip Manufacturer Wholesale Cartridge Compression Spring Greenhouse Accessories Slot Circlip

Greenhouse shed circlip dipped plastic circlip manufacturer wholesale cartridge compression spring greenhouse accessories slot circlip

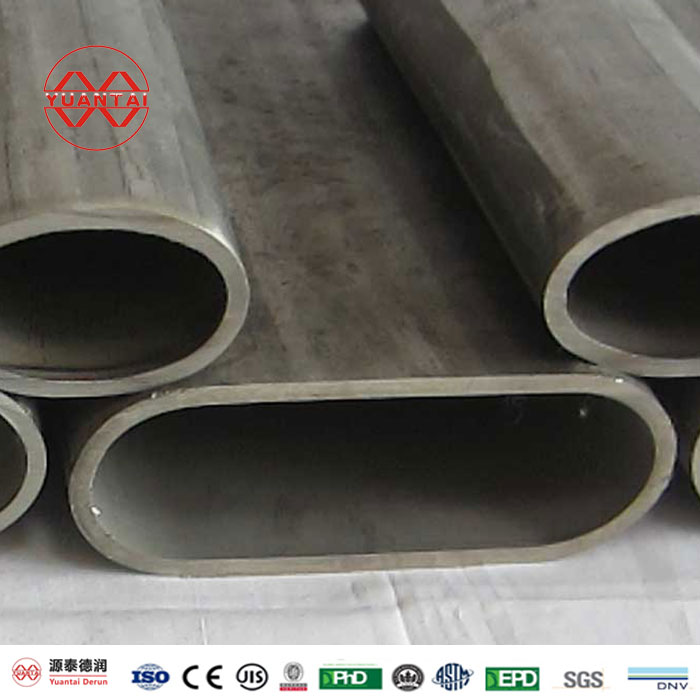

Wholesale Hot-Dip Galvanized Oval Pipe Q235B Galvanized Steel Pipe Installation Of Bendable Greenhouse Pipe

The energy-saving solar greenhouse is the most economical and practical greenhouse type among greenhouse types, because this type of greenhouse can be used for winter vegetable cul […]

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]