For countless construction undertakings, HDPE pipe is the go-to solution due to its incredible range of advantages. Suited to a plethora of applications, the product is made from resilient thermoplastic polymers and is resilient to numerous types of chemicals. HDPE pipe is lightweight, easy to manoeuvre and insert, and economically viable – yet, if you’re wanting to get the most out of your HDPE pipe, it’s key to comprehend the ovality tolerance surrounding it.

Exploring the Bendability of HDPE Pipes

The circumference of HDPE pipe should not deviate more than 5% from a perfect circle—this is its ovality tolerance. That is, the level of allowable deviation in the shape of the pipe cross-section should not exceed 5% from what a perfect circle would look like. This tolerance serves as an indicator of how closely the pipe resembles its ideal shape.

Unveiling the Significance of HDPE Pipe Ovality Tolerance

When it comes to HDPE pipe ovality tolerance, staying on top of it is essential. This is because a pipes’ roundness and uniformity has a huge impact on its flow dynamics and pressure loss, both of which can be affected by excessive ovality. If these are left uncorrected, they can significantly compromise pipe performance. Therefore, adhering strictly to HDPE pipe ovality tolerance should be prioritized in order to guarantee optimal performance.

The ovality of HDPE pipe is paramount for its soundness. A substantial departure in roundness could result in a muscular frailty, leaving it even more prone to crash. Moreover, an ovality divergence could give cause for the pipe to be crooked, making it hard to fasten, thereby producing a hazard. Staying true to HDPE pipe ovality tolerance guarantees that the pipe can be used without putting anyone at risk.

Ultimately, managing HDPE pipe ovality is a matter of aesthetics. Even a minor defect in the shape of the pipe can ruin its overall appearance and diminish the beauty of the entire installation.

Guaranteeing Optimal CPVC Pipe Roundness Tolerance

Ensuring optimal HDPE pipe ovality tolerance is largely a matter of careful selection. It is essential to select the HDPE pipe best suited to the application in question, as the ovality tolerance of each one can differ substantially. Making an informed choice is key to successfully meeting this tolerance requirement.

Achieving the desired ovality tolerance largely depends on following the manufacturer’s instructions and using appropriate tools while installing the pipe. Proper precautions taken during installation can guarantee a successful outcome.

On a regular basis, the pipe should be surveyed for evidence of ovality deviation. If any irregularities are noticed, steps should be taken without delay to arrest any additional deviations.

Maintaining a proper ovality tolerance of the HDPE pipe during installation is of utmost significance to guarantee its performance, safety, and attractiveness. Careful procedures as well as regular examinations of the pipe can expedite adherence to the ovality tolerance for the HDPE pipe and help ensure an optimum outcome.

The superior performance of HDPE pipe in many industries is thanks to its unparalleled strength, flexibility, and durability. From water distribution systems to gas and oil transmission lines, HDPE pipe works hard to deliver reliable results in a wide range of industrial applications. Ensuring the highest quality of the material means carefully monitoring its ovality, or roundness. It is essential to be familiar with ovality tolerance in terms of HDPE pipes, so that their performance can be fully optimized.

Comprehending Ovality Tolerance of HDPE Pipe

HDPE pipes must adhere to a certain level of roundness, often referred to as ovality tolerance. This is ascertained by comparing the maximum and minimum diameters along the length of the pipe, with the permissible variance decided by the manufacturer, though typically between 0.5-1.5% of the pipe’s standard diameter. For instance, if an HDPE pipe of 6” diameter is subject to an ovality tolerance of 0.5%, then it should have a maximum circumference of 6.03” and a minimum one of 5.97”.

Unveiling thesignificance of HDPE Pipe Ovality Tolerance

Achieving the correct ovality tolerance for HDPE pipe is critical since it affects its ability to remain strong and endure throughout its lifetime. If the pipe is not circular enough, it will be vulnerable to damage and able to leak. Furthermore, if the ovality tolerance is too limiting, the pipe will be hard to fit properly with fixtures. On the other hand, if the ovality tolerance is too loose, it could cause the pipe to bend or collapse over time, consequently deteriorating its quality and performance and possibly resulting in failure.

Examining the Effects of Variables on HDPE Pipe Ovality Tolerance

Several elements can impact the ovality tolerance of HDPE pipes, with the quality of the starting materials typically being of paramount importance. If superior components are used, it is likely that the ovality tolerance can be maintained more effectively. Additional matters worth considering when it comes to ovality tolerance are those related to the manufacturing process such as heat and pressure inside the extruder, plus the type of tooling utilized.

Testing Accuracy of Ovality in HDPE Pipe

In order to assess the ovality of HDPE piping, a device known as an ovality tester is employed. This tool gauges the pipe’s maximum and minimum diameters over its length. All results are then weighed against the established ovality boundary to ensure the pipe production stands up to the laid criteria.

Knowing the ovality tolerance of HDPE pipe is essential in assessing its quality and performance. Raw material quality, production methods, extrusion temperature and pressure, and tooling all have influence on the ovality tolerance, which is inspected with an ovality tester and must conform to predetermined standards. Without this, one cannot properly judge the suitability of the pipe for a given application.

Post time: 2023-08-20

Related Product

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]

Supply Of Zigzag Steel Clips New Type Of Zigzag Steel Framework Connecting Clips

Product name: Jizi steel skeleton accessories Product alias: zigzag steel card, zigzag steel bending connection Product description: The framework of the shed is made of zigzag ste […]

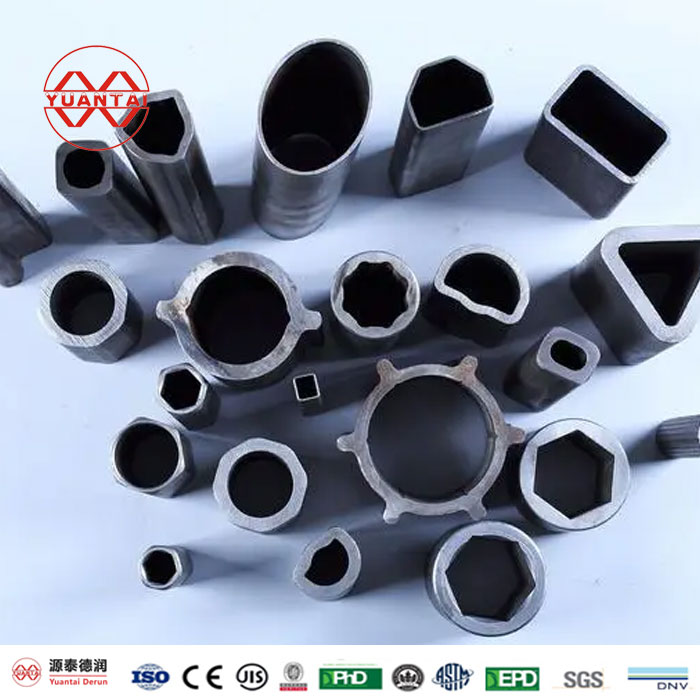

Six Angle Steel Tube,Hexagon Steel Pipe Outer Six Inner Circular Special-Shaped Steel Pipe

Hexagonal steel pipe is also called special-shaped steel pipe, including octagonal pipe, rhombic pipe, elliptical pipe and other shapes. It is an economic section steel pipe, inclu […]

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

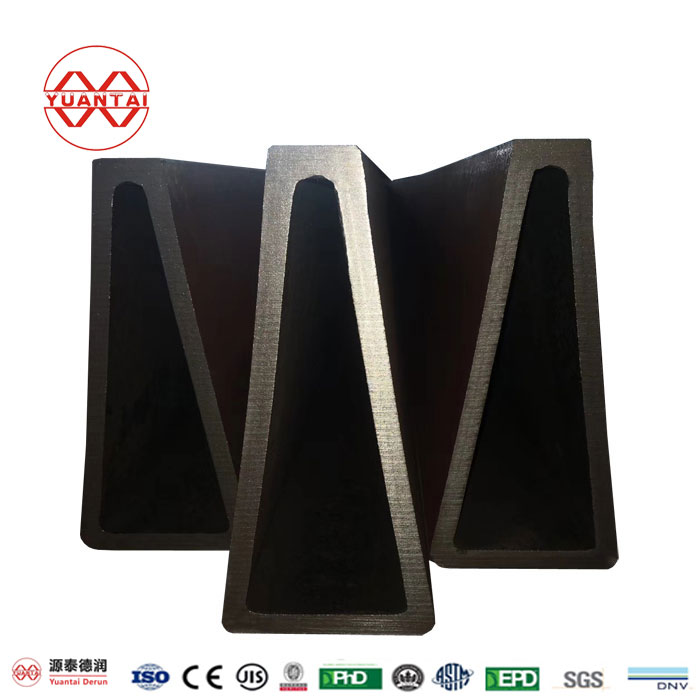

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

Greenhouse accessories Film roller, super strong side film roller Top windproof film roller

The shell is made of cast aluminum, which is cast by precision die-casting one-time molding process. Its raw materials and casting quality are in sync with the domestic top tier br […]

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

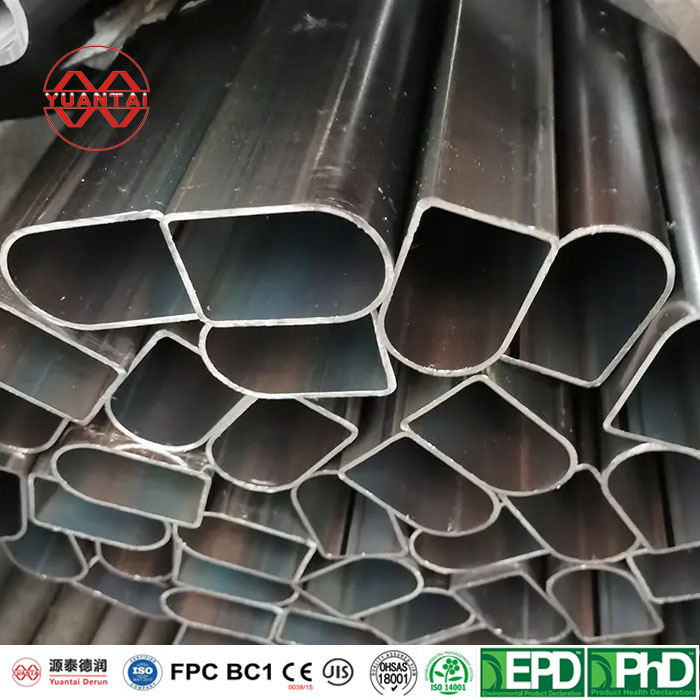

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]