A pipe’s ovality is often a primary concern in the Piping industry as pipes can tend to bend when presented with fluctuating temperatures or pressures. To guarantee a pipe meets required safety and performance levels, the ovality must be quantified. This article is intended to explain the formula for calculating ovality and its value within the industry.

Ovality can be computed by finding the variance between the major and minor diameters of the pipe. The major size is taken from the longest length of the tube while the minor is measured from the shortest edge. To find the ovality, the formula goes as such:

Difference between Major and Minor Diameters divided by the Major Diameter is known as Ovality.

To calculate the ovality of a pipe, no matter its size or which material it’s composed of, this formula can come in handy. Expressing the ovality as a percentage is the norm. For instance, if a pipe’s major and minor diameters are 10 inches and 9.8 inches respectively, then its ovality is 0.2/10 = 0.02 which converts to 2%.

The shape of a pipe is an aspect of vital concern for the safety, performance, and longevity of the pipe. Should its ovality exceed a certain limit, it can become weakened and cause issues such as lower flow efficiency which can negatively affect operation. What’s more, higher ovality can make the pipe less robust against corrosion and other forms of wear and tear.

The ovality of a pipe can be critical for its success in a given application or industry. The threshold for acceptability can swing from as little as 1-2%, depending on the field. To guarantee optimal utilization, it’s important that any utilized pipe stay within the accepted range of ovality.

Pipe ovality can be discerned with the power of manual math or with more comprehensive software. Figuring out its shape by hand requires taking measurements of the pipe and using the necessary formula. Software, however, takes the process a step further. It is more reliable and can factor in variables such as material thickness and temperature to achieve a more precise result.

At the end of the day, pipe ovality is an indispensable factor to keep in mind when working with them. The equation for figuring out a pipe’s ovality is easy and can be used to calculate ovality of any pipe. It is essential to guarantee that the ovality of a pipe abides by the given tolerances for the particular application in order to guarantee the safety and efficacy of any project.

Evaluating the ovality of a pipe is crucial for determining the impact it has on liquids and material moving through it. The ovality smalls formula is utilized to precisely gauge the oval shape of a pipe, based on its inner and outer diameters as well as circumference. In this particular article, we’ll explain the Ovality Smalls Formula and look at its uses in pipe, tube, and ducting measurements.

The ovality smalls formula is an equation that calculates a pipe’s ovality by using the inner and outer diameters and the circumference of the pipe. The calculation is represented as such:

The Differing Range of Ovality Between Outer and Inner Diameters Divided by Circumference

To measure the ovality of a pipe in millimeters or inches, a handy formula exists. Before utilizing it, you must determine the inner and outer diameters of the tube. To find the outer diameter, take the measurement from the external side of the pipe; for the inner diameter, measure from within. Afterwards, calculate the circumference using this equation:

By adding together the outer and inner diameter, and then multiplying it by , you can arrive at the circumference of any shape.

With the inner and outer diameters, as well as the circumference, in hand, it’s possible to utilize the ovality smalls formula to ascertain the ovality of a given pipe. The answer provided by this mathematical approach is expressed as a numerical value that implies the ovality of the pipe in either millimeters or inches.

An accurate ovality measure is vital when it comes to pipe measurement – if it’s off, an impact on the material flow can be observed. When too out of round, the fluid running through the pipe will be disrupted, possibly causing a decrease in functionality as well as extra wear on the pipe. Additionally, having a precise ovality measurement aids with the effectiveness of choosing a suitable fitting for said pipe. If the ovality is too large it can disrupt the fit of the joint creating safety holes or other issues. The Ovality Smalls Formula can be used to verify the correctness of these appraisals and guarantee that both the pipe and fitting are flawlessly secure and efficient.

Taking all of its factors into account, the ovality smalls formula is imperative for precisely discerning the shape of a pipe. Utilizing the inner and outer diameter, plus the circumference, of the pipe, it is a feasible way to calculate ovality in millimeters or inches. Knowing a pipe’s ovality is vital for manufacturing a seamless flow of material and checking the precise size of fittings.

Post time: 2023-08-25

Related Product

Greenhouse Shed Circlip Dipped Plastic Circlip Manufacturer Wholesale Cartridge Compression Spring Greenhouse Accessories Slot Circlip

Greenhouse shed circlip dipped plastic circlip manufacturer wholesale cartridge compression spring greenhouse accessories slot circlip

8-Shaped Steel Pipe

8-shaped steel pipe Product Information Brand: YuantaiDerun Place of Origin: Tianjin, China Alloy Or Not: Non-Alloy Special Pipe: Thick Wall Pipe Standard: ASTMA500/A501/A53,BS1387 […]

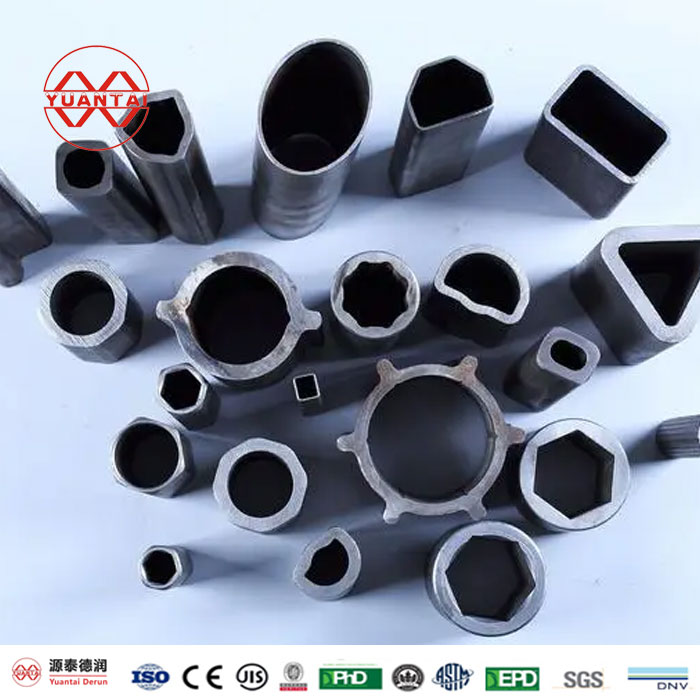

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe

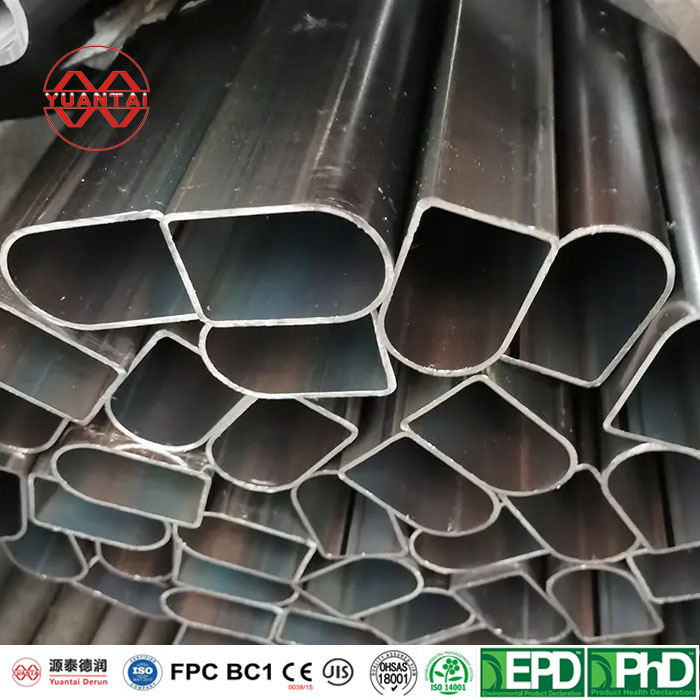

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

Steel Wire Ground Anchor, Fixed Pressure Film Rope For Greenhouse, Ground Anchor, Embedded Part Of Ground Pile For Greenhouse, Steel Wire Ground Anchor

Steel wire ground anchor, fixed pressure film rope for greenhouse, ground anchor, embedded part of ground pile for greenhouse, steel wire ground anchor Steel wire anchor is directl […]

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]

Greenhouse accessories Film roller, super strong side film roller Top windproof film roller

The shell is made of cast aluminum, which is cast by precision die-casting one-time molding process. Its raw materials and casting quality are in sync with the domestic top tier br […]