Working with metal can be a complex process and creating custom-shaped stainless steel tubing takes special precision. An expertise in the art of stainless steel tube bending is required to form tubing to a desired shape. Here, we will take an in-depth look at the craftsmanship of custom stainless steel tube bending, the tools that make it happen, and the advantages of using this process.

Custom stainless steel tube bending is a complex craft. Taking a piece of material and forming it into the envisioned shape demands a skilled hand and specialized tools. Doing so with precision brings the process to an art form, guaranteeing that the desired outcomes are eventually attained.

From mandrels to roll benders, stainless steel tubes can be molded into practically any shape imaginable using a range of bending machines. Mandrel-style machines are ideal for tubes with a radius less than 1.5 inches, whereas for large radii the rotary draw bender is the ideal choice. For curving complex forms, or if the radius exceeds six inches, roll benders can be used to shape the metal accordingly. Regardless of the desired shape and material being used, custom stainless steel tube bending boasts a wide range of machine tools designed to fit any bill.

When it comes to metal fabrication, custom stainless steel tube bending stands out as a premier choice. This method is great for making complex shapes that would not be achievable via other methods. Not only is this technique extremely efficient, but it’s incredibly cost effective as well. Moreover, production is able to occur quickly, translating to shorter lead times for projects.

With its impressive durability and corrosion resistance, custom stainless steel tube bending is a reliable choice when it comes to applications in high-pressure settings. Its lightweight design further fortifies its suitability in scenarios where the weight of the material is crucial. Ultimately, this material has proven its worth in many grim environments, making it a great option for any specialized purpose.

Expertise and the right tools are paramount for achieving intricate designs and sturdy structures with custom stainless steel tube bending. This economical and effective technique delivers corrosion defense, making it an outstanding choice for even the most challenging of conditions. Crafting intricate shapes that would be unachievable via other methods, this highly durable tubing provides a vast range of possible configurations.

The art of custom stainless steel tube bending is an involved process that starts with understanding and fulfilling customer specifications. Both bending and forming are utilized in the careful manipulation of metal parts so that they may match the exact characteristics desired. Expertise in this task calls for a nuanced understanding of the skills and tools needed to get exactly what a customer needs.

The robustness of stainless steel, a combination of metal such as iron, chromium, and other chosen components, offers unparalleled protection against corrosion. Its dependability and affordability make this alloy a go-to for many functions. Similarly, the non-toxicity and inherent antibacterial elements of stainless steel make it suitable for applications in the medical, Food & Beverage industries.

When it comes to bending stainless steel tubes into their desired shape and size, highly trained and experienced technicians are essential. The process itself requires a collection of machines and tools, from press brakes and benders to rollers. However, the selection of apparatuses depends on the magnitude and complexity of the project at hand.

Gauging the exact dimensions of the tube is the beginning and key to a successful stainless steel tube bending experience. Careful observations must be made as these measurements will provide insight into the essential angles and force necessary to produce a desirable result.

With the dimensions obtained, it’s time to pick a tool proper for the task. What sort of bend is being made determines which one applies; if it’s straight, press brakes work best, but for intricate forms you’ll need benders/rollers.

Before bedding, the tube must go through a rigorous clean-up process to ensure that no dirt or particles remain within its surface. Once that is complete, it is time to secure the item in the machine. The operator takes control and sets adjustments to guarantee that the desired force and angle are attained. With a secure fit and appropriate settings chosen, the tube is ready to bend.

Upon reaching the optimal adjustments, the person in charge can initiate the bending task. Following the operation of the equipment, the tube will be gradually bent to attain its preferred form. Upon completion, the product is inspected for any irregularities incurred during its transformation. If evidence of flaws is observed, it is imperative to cease progress and make the essential tweaks before finishing the bend.

After the tube has been skillfully curved to precision, it is then ready to be further processed. This could comprise of facets such as sprucing up, fusing, or a fresh coat of paint. Ultimately, the end product needs to be combed through to guarantee that it encompasses all the specifications requested by the customer.

Forming stainless steel tubing to the desired specifications can be a difficult process, requiring proficiency with particular tools and techniques as well as an understanding of the complexities involved. It may be a lengthy and expensive endeavour, but the effort put forth often yields excellent outcomes, specifically tailored to the customer’s exact requirements.

Post time: 2023-07-11

Related Product

Supply Of Zigzag Steel Clips New Type Of Zigzag Steel Framework Connecting Clips

Product name: Jizi steel skeleton accessories Product alias: zigzag steel card, zigzag steel bending connection Product description: The framework of the shed is made of zigzag ste […]

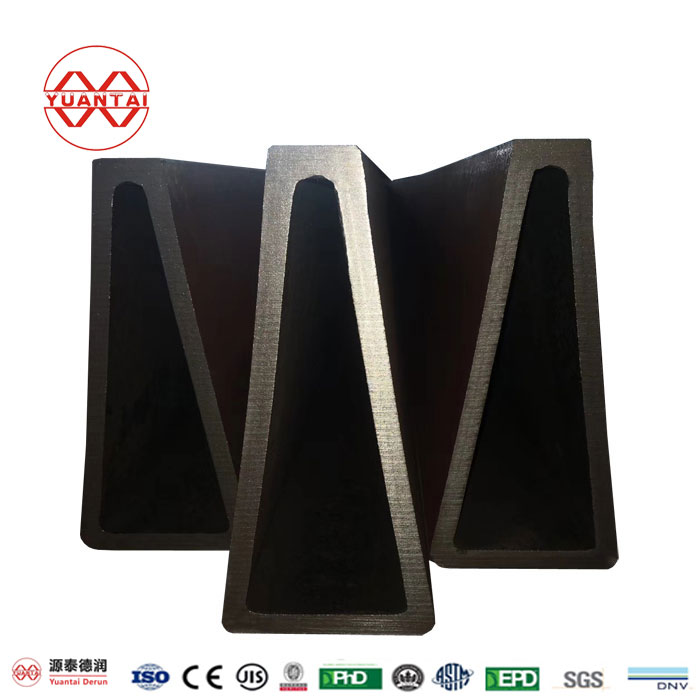

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

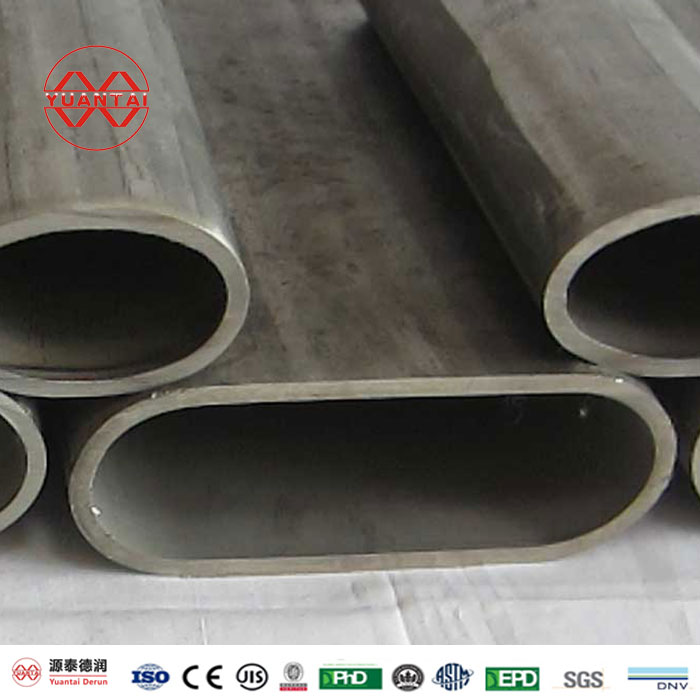

Wholesale Hot-Dip Galvanized Oval Pipe Q235B Galvanized Steel Pipe Installation Of Bendable Greenhouse Pipe

The energy-saving solar greenhouse is the most economical and practical greenhouse type among greenhouse types, because this type of greenhouse can be used for winter vegetable cul […]

OVAL TUBE BASE GREENHOUSE ACCESSORIES OVAL TUBE GREENHOUSE CONNECTOR CLAMP

The base of oval tube in greenhouse is no stranger to those who have been exposed to greenhouse equipment. In the installation project of greenhouse equipment, the products of oval […]

Driving Motor Of Sunshade Curtain Inside And Outside The Greenhouse

Product alias: decelerator sun shading system motor window opening motor external sun shading motor Specification: 380V 750W As one of the important equipment used in the greenhous […]

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

Hot Dip Galvanized Coping Spring

Hot dip galvanized coping spring Essential details Size:Small Type:Single-Span Agricultural Greenhouses Cover Material:Galvanized or black painted Loas Type:Grasping Wire D […]

Six Angle Steel Tube,Hexagon Steel Pipe Outer Six Inner Circular Special-Shaped Steel Pipe

Hexagonal steel pipe is also called special-shaped steel pipe, including octagonal pipe, rhombic pipe, elliptical pipe and other shapes. It is an economic section steel pipe, inclu […]

Octagonal Steel Pipe

Tianjin Yuantai Derun Group has 18 wholly-owned subsidiaries, of which Tianjin Yuantai Technology Development Co., Ltd. was founded in 2014 to produce super large diameter, super t […]