Stainless steel pipe is a kind of hollow long round steel, which is widely used in petroleum, chemical industry, medical treatment, food, light industry, machinery and other industrial conveying pipelines and mechanical structural parts. In addition, when the bending and torsional strength is the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. Also, because of its good corrosion resistance, it is the material used to make heat exchanger, condenser and other equipment in the chemical, petroleum, textile and other industries.

There are many types of stainless steel pipes, such as austenitic stainless steel pipes, super austenitic stainless steel pipes, ferritic stainless steel pipes, duplex stainless steel pipes, precipitation hardening stainless steel pipes, and the like. According to the shape, it can be divided into round stainless steel pipes and special-shaped stainless steel pipes. According to the requirements of use, it can be divided into general purpose stainless steel pipes and food hygiene stainless steel pipes.

General-purpose stainless steel pipes are mainly used in the construction, machinery and vehicle industries. The main grades are 304, 304L, 321, 316, 316L, 317L, 347, 347H, 310S, 904L and so on. The outer diameter of hot-rolled seamless pipe is generally greater than 32mm and the wall thickness is 2.5-75mm. The diameter of cold-drawn seamless pipe can be 6mm and the wall thickness can be 0.25mm. The stainless steel pipes produced in our country can be broadly divided into two types according to their manufacturing process: hot rolled stainless steel pipe and cold rolled stainless steel pipe.

The main difference between hot-rolled and cold-rolled stainless steel pipes lies in their manufacturing process. Cold-rolled stainless steel pipes are made of hot-rolled stainless steel pipes as raw materials, and their finishes and dimensions are all produced according to ASTM A312. In order to ensure the precision of the dimensions and the smoothness of the surface of the cold-rolled stainless steel pipe, cold drawing (cold drawing) or cold rolling (cold rolling) is performed on the basis of hot-rolled seamless steel pipes. Cold-drawn (cold-drawn) stainless steel pipes are usually small-diameter stainless steel pipes. The wall thickness of cold-drawn pipes is generally not more than 4mm, and the wall thickness of cold-rolled pipes can be 0.25mm. The products made by cold drawing process generally have higher dimensional accuracy and smoothness than hot-rolled products, and the surface is bright and beautiful.

The main difference between cold-rolled and hot-rolled seamless stainless steel pipes lies in their manufacturing process. The manufacturing process of hot-rolled seamless stainless steel pipes includes piercing, hot rolling and hot drawing, while the cold-rolled seamless stainless steel pipes are made of round billets through cold drawing, cold rolling and cold drawing. The hot-rolled seamless stainless steel pipes are generally used in applications where the pipes are required to have highstrength and high toughness, such as in petrochemical and natural gas industries. The main grades of hot-rolled seamless stainless steel pipes are 304, 304L, 321, 316, 316L, 317L, 347, 347H, 310S, 904L, etc. The outer diameter of hot-rolled seamless pipe is generally greater than 32mm and the wall thickness is 2.5-75mm. The cold-drawn seamless stainless steel pipes are generally used in applications where the pipes require precision dimensions and smooth surfaces, such as in automotive, electric and hydraulic industries. The main grades of cold-drawn seamless stainless steel pipes are 304, 304L, 321, 316, 316L, 317L, 347, 347H, 310S, 904L, etc. The diameter of cold-drawn seamless pipe can be 6mm and the wall thickness can be 0.25mm.

The main difference between hot-rolled and cold-rolled seamless stainless steel pipes lies in their manufacturing process. The manufacturing process of hot-rolled seamless stainless steel pipes includes piercing, hot rolling and hot drawing, while the cold-rolled seamless stainless steel pipes are made of round billets through cold drawing, cold rolling and cold drawing. The hot-rolled seamless stainless steel pipes are generally used in applications where the pipes are required to have highstrength and high toughness, such as in petrochemical and natural gas industries. The main grades of hot-rolled seamless stainless steel pipes are 304, 304L, 321, 316, 316L, 317L, 347, 347H, 310S, 904L, etc. The outer diameter of hot-rolled seamless pipe is generally greater than 32mm and the wall thickness is 2.5-75mm. The cold-drawn seamless stainless steel pipes are generally used in applications where the

Post time: 2023-06-25

Related Product

New Type Hot Dip Galvanized Bent Pipe For Greenhouse

Curved pipes for greenhouses are commonly used to build steel framed greenhouses for vegetables. Below are the high-definition pictures and quotations of curved pipes compiled by X […]

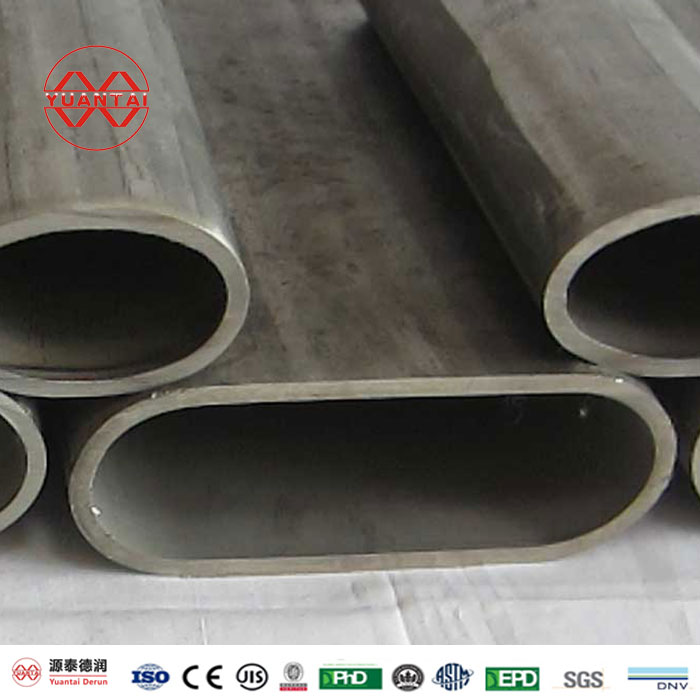

Wholesale Hot-Dip Galvanized Oval Pipe Q235B Galvanized Steel Pipe Installation Of Bendable Greenhouse Pipe

The energy-saving solar greenhouse is the most economical and practical greenhouse type among greenhouse types, because this type of greenhouse can be used for winter vegetable cul […]

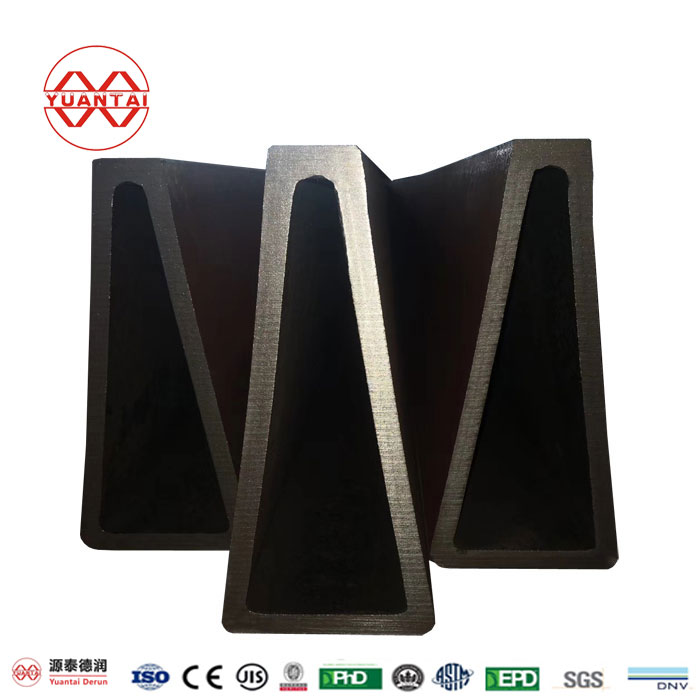

Trapezoidal Steel Pipe

Trapezoidal steel pipe is provided with a pipe body. The section of the pipe body is isosceles trapezoid. The angle formed between the long bottom edge of the trapezoid and the two […]

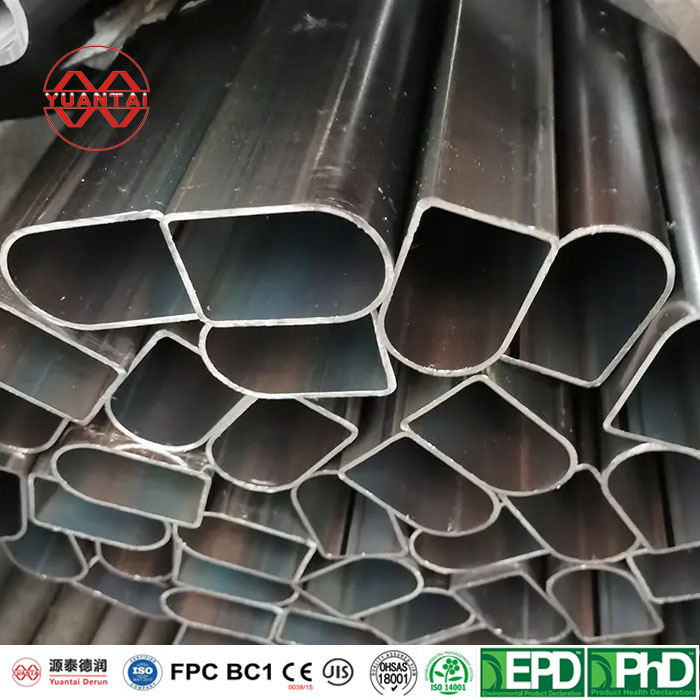

D-Shaped Steel Pipe

D-section steel pipe also called D-section steel. D-shaped steel pipe is a kind of special-shaped pipe, so special-shaped seamless steel pipe is widely used in various structural p […]

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP

GREENHOUSE ACCESSORIES T-CLAMP T-FIXING CLIP ssential details Size:Large Material:PE Type:Single-Span Agricultural Greenhouses Cover Material:Film Layer:Single Place of Orig […]

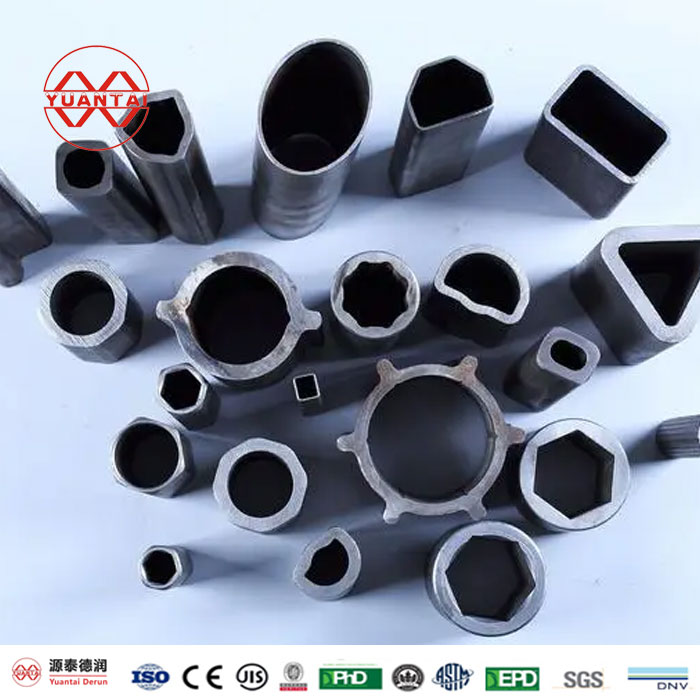

Special Shaped Steel Pipe Factory

Special shaped steel pipe factory

OVAL TUBE BASE GREENHOUSE ACCESSORIES OVAL TUBE GREENHOUSE CONNECTOR CLAMP

The base of oval tube in greenhouse is no stranger to those who have been exposed to greenhouse equipment. In the installation project of greenhouse equipment, the products of oval […]

Canopy fixed hook, sink hook, press film with hook

About company Our company produces and sells greenhouse accessories and greenhouse film reelers. The main products are: greenhouse accessories, side film reelers, roof film reelers […]

Special Shaped Seamless Steel Pipe

Special shaped seamless steel pipe